Carl Cloos develops spatter protection for hollow workpieces

Carl Cloos Schweisstechnik GmbH, Haiger, Germany, has developed a unique system to avoid stubborn spatter residues in a component's interior that arise when hollow workpieces, in particular, pipes, are welded together.

The tightly adhering weld spatters in the area of the connection point, often have a negative effect on the function of the components and have to be removed in a time-consuming, expensive way. It is particularly critical if the interior of a pipe is a functional surface.

Among others, the newly developed spatter protection is used successfully when various hydraulic cylinders are welded together using the MSG laser hybrid welding process, which requires a free root without weld pool backing for a full penetration. It is essential that the laser beam can freely penetrate the pipe walls, whereby the pipe interior is strongly damaged because of the spatter adhesion.

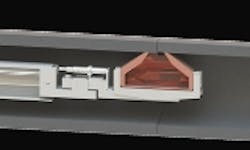

The new spatter protection system is based on a 3D suspended collecting bin with sealing contours that adapt exactly to the pipe's inner surface. The advantage of the system is that the laser beam as well as the weld spatters are centrally collected in the bin. Thus, the component's inner surface remains clean and there is no need for an expensive reworking.

The spatter protection is automatically positioned directly below the weld seam by means of the NC travel unit in order to be located exactly where the pollution of the component has to be prevented. An integrated electronic query ensures that the welding process is only started when the spatter protection is really fit tightly to the component interior. After a large number of weld seams, the collection bin must be emptied. This is done by a simple removal and without additional tools.

The new spatter protection offers an enormous savings potential in all ranges of the container and pipe manufacture. Additional operations are avoided and any product design is possible, independent of probable weld spatters.

The image shows the newly developed CLOOS spatter protection system. The collecting bin for the weld spatters is located directly below the connection point of two pipes.