Hannover, Germany -- Laser Zentrum Hannover e.V. (LZH) is using laser micromachining techniques to develop innovative technologies for improved insertion techniques and exact fitting of cochlea implants in the inner ear, as well as better quality for residual hearing.

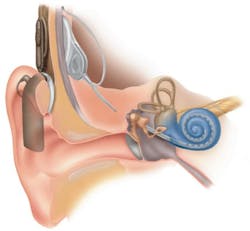

Approximately 95% of people who are highly hearing-impaired have an adequately intact auditory nerve, enough to provide at least partial hearing. A cochlea implant (CI) electronic acoustic prosthesis can take over the function of damaged sensory cells in the inner ear. This aid consists of: an implant, placed in the bone under the skin behind the ear; an electrode, placed directly in the cochlea; and a microphone and speech processor, also placed behind the ear. (Delicate insertion of the electrode into the cochlea is critical to avoid damaging the basilar membrane, the center for hearing sensory cells.) When sound waves are registered by the microphone, they are "translated" into a series of electrical impulses, which are led to the electrode on the auditory nerve in the inner ear.

LZH's Surface Technology group has come up with a way to simplify and improve the operation of inserting the electrode into the cochlea. They manufacture the CI electrodes with nickel-titanium shape memory alloy (NiTi-SMA); when heat or electrical impulses are applied, the material "remembers" the form or shape in which it was manufactured, allowing specific movement and fitting of the electrode. Laser melting creates a highly individualized NiTi-SMA implant, which can then be inserted more deeply into the cochlea without damaging the basilar membrane, which translates to better hearing.

The LZH group Laser Micromachining also is working to improve the surface of the cochlear implants through laser structuring. By using a femtosecond laser on the platinum electrodes, special nanostructures can be manufactured to reduce attachment of connective tissue and improve interaction with the nerve cells. Nanostructuring also decreases frequency-dependent electrical resistance, meaning less energy is needed.

A special challenge is that the structures must be made on an implant only 300 μm in diameter, and with a curved surface; LZH is currently working on a unit which can provide these complex structures on a very small scale.

The LZH's work in cochlear implants are financially supported within the framework of the German Federal Ministry of Education and Research (BMBF) project Gentle CI, and by the interdisciplinary special research program 599 of the German Research Foundation (DFG). Among the project partners is the Hannover Medical School (MHH), which has the world’s largest cochlea implant program for the extremely hearing impaired.

Cochlea implant with an external microphone and micro-speech-processor. (Source: Cochlear)

Sponsored Recommendations

Sponsored Recommendations

Optical Power Meters for Diverse Applications

April 30, 2024

Request a free Micro 3D Printed sample part

April 11, 2024

Voice your opinion!

Voice your opinion!