3D scanning system for laser drilling

Arges, a Wackensdorf, Germany OEM laser component manufacturer, has released a new 3D scanhead system for advanced laser drilling applications.

The Elephant is a 7-axes galvanometer-driven scanning system, adapted for use with ultrashort pulsed lasers (e.g. femtosecond lasers) to allow a fast ablation of different materials with minimal thermal influences on the surrounding area of the processing zone. Its standard version comes with three apertures (16-21-31 mm) addressing four wavelengths: 355 nm, 532 nm, 1064 nm, and 1550 nm.

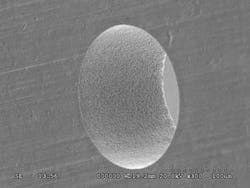

Elephant is especially tuned to create holes with flexible geometries, such as variable hole diameters and ellipsoidal holes with a high aspect ratio. Applications include filters, textiles, medical devices, and materials science -- one specific application is drilling nozzles, e.g. conical holes in fuel injectors. Holes can be created with defined tapers (negative, zero, or positive) and taper angle in ranges of up to 10 μm -- opening up microholes with a hole diameter range of 50-500 μm and a diameter repeatability of < 0.4%. Cycle time at the drilling of injector nozzles is < 2 sec/hole on 200 μm diameter, 200 μm thick 440 stainless steel.