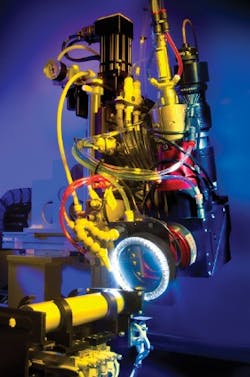

Microlaser welding automation

Automation Engineering Inc., Wilmington, MA, has released a new version of its microlaser welding station that can perform a variety of vision-guided tasks, including laser welding, marking, cutting, and drilling.

The VGLase, an upgrade of the company's FlexLase station, uses configurable machine vision and motion control to implement precision laser welding, laser drilling, laser cutting and laser marking. End users can easily define new or modified laser paths and patterns without formal training or experience with programming, reducing setup time. Using machine vision to adjust laser paths automatically, compensating for dimensional variations from part to part, enables more accurate laser processing. Among the system's features and benefits:

- Highly flexible for different processes and laser processing patterns

- Fully integrated machine vision

- Interchangeable fixturing and automated material handling options

- Split beam laser delivery

- Vision guided laser trajectory

- Up to 6-axis motion control

- Automated components load/unload

- Automated re-align of welded components based on force monitoring during welding (< 1μm)

The VGLase targets a range of applications: laser welding for photonics/optoelectronics, medical devices, and battery cells; laser cutting for solar cells; and laser cutting/drilling for circuit boards and substrates for electronics. For example, the VGLase system can be set up to hermitically seal (laser weld) and etch (laser mark) basic battery assemblies, including top and bottom welds and bottom and side etching; weld and etch are fully automated, with the exception of cell handling.