Happy holidays, brought to you by lasers

Nashua, NH - We at ILS wish all our readers, contributors, partners, advertisers, and industry friends a very happy holiday season. To that end, we also enjoy sharing with you laser material processing-related news relevant to the seasonal cheer. Enjoy!

Fiber laser-cut Xmas tree in three reflective metals

JK Lasers, no stranger to holiday-themed laser activity, is back at it again, this time with a special festive tree: 1 mm brass with 1 mm aluminum snowflakes and 1.5 mm red anodized aluminum baubles, all cut with a 1 kW fiber laser (the JK1000FL) and nitrogen assist gas. This was possible, the company points out, thanks to its integrated back-reflection protection that directs reflected light away from the delivery fibers and into a beam dump. Using this technology, the JK1000FL can achieve up to 12 m/min and 11 m/min speeds for 1 mm brass and 1 mm aluminum, respectively (depending on the assist gas and motion system, and the profile to be cut). Here's a video of the tree-cutting in action.

Past JK Laser holiday projects -- each utilizing a different laser, processing technique, or material -- have included Diwali, the Hindu Festival of Lights (nice touch with the sparklers); the US flag for the 4th of July; an Easter egg; and a dragon for the Chinese New Year.

Laser-cut Christmas card

This is no ordinary holiday greeting card -- its detail is nothing short of astonishing. Iggesund Paperboard is the source, but it's a collective showcase for the van Heertum Design agency and several Dutch suppliers (laser cutting is done by Point to Paper.) This particular card is made in Invercote Creato 350 g/m2, whose "superior tear strength" enables keeping this card in one piece. The starry-sky motif with reindeer and celestial objects is done in an extremely fine laser cut, with the laser-cut sections attached using tiny tabs.

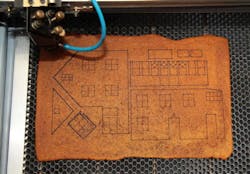

Laser cut gingerbread house

This one falls more in the category of home laser enthusiast. Johan von Konow offers a step-by-step walkthrough of his project to build a miniature gingerbread house, using a refurbished 50 W laser engraver in two steps (80% power for the cutout lines, and 20% for the decoration lines which doubled as guides for subsequent frosting). Key to this process was baking the gingerbread sheets first so they'd be easier to process with a laser, hardening the soft material to eliminate distortion and warping. No amount of prep could solve one problem, though: "Lasers tend to create a lot of smoke, and this one was worse than usual. It was something between burned cake and burned hair." The finished product was inedible but still a delightful model of his actual house.

(via vonkonow.com)

Of course he's not the only one to figure out that it's cool to join the holiday spirit with some lasers. A tech shop in Madison, WI goes into a little more description of its efforts to laser-cut and create its own gingerbread house, using a 150W machine (apparently one from China) with plans created through Inkscape and Corel Draw. Among their advice: cut at a speed of 15, power 100, and corner power 60; and test-cut with cardboad pieces first. (And they agree, smoldering gingerbread smells bad.)