Small-volume laser welding system for auto plants

Soutec AG, a Neftenbach, Switzerland, supplier of laser welding and cutting systems, has introduced a new compact laser welding system for automotive use, targeting smaller production needs at distributed facilities.

Decentralization of the global automotive industry, along with growth in new markets, has spurred automotive manufacturers to establish peripheral manufacturing locations, often far away from main production plants, to help mitigate fluctuation in production volumes. These sites are not suitable for high-volume or high-performance tailored blank (TB) welding systems. At the same time, they still require process reliability and welding quality.

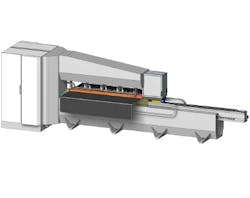

Thus Soutec is unveiling the Soupact compact laser welding system, which can weld materials such as boron steel and a range of aluminum alloys (using fiber, disk, or diode laser sources), for sheet metal thickness of 0.5-3.0 mm, for prototyping or batch production runs. A continuously measuring seam tracking and quality control system regulates wire speed to ensure sufficient material is always present in the melting pool. Gap closing <0.3 mm between sheet metal is done with additional filler wire. Seam length ranges from 200-2000 mm (100-2500 mm is optional), on blank sizes of 150-700 (thin) to 700 mm for thick parts, with options to be smaller or larger on request.

The system can be packed for shipping in a 40' container, reducing shipping costs; it can also be easily dismantled and moved in a 40' container to another location, as a backup machine to provide production flexibility. Soutec says it has already sold the new Soupact system "to a Tier 1 firm of FAW and VW in China."