Researchers: Adjusting beam polarization can improve laser micromachining

Liverpool, UK Researchers at the U. of Liverpool say they have developed a new optical technique capable of producing laser beams with unusual modes of electric field, increasing process efficiency and quality of laser micromachining.

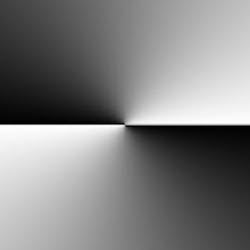

Laser micromachining with linear polarization (i.e. the beam's electric field is vertically oriented) is used in a wide range of precision manufacturing applications, from drilling holes for fuel injection nozzles to processing silicon wafers and medical stent devices. Using a 100 fs laser pulse with a spatial light modulator and a wave plate, scientists at the school's Liverpool Laser Group have demonstrated what they say is a cost-effective way to produce laser beams with different polarizations -- radial and azimuthal -- that rotates the polarization in any desired direction to interact with any material for laser micromachining.

"This technology and these new modes of polarization enabled us to achieve significant gains in processing speed and quality when micro-machining stainless steel plates," explains Olivier Allegre, part of the team based at the Lairdside Laser Engineering Centre in Birkhead led by Professor Ken Watkins. "A radially polarized beam increased the machining speed, due to the higher absorption of radial polarization which increases the coupling of the laser energy during machining."

Their work will next progress to see how the technique can improve processing of materials including semiconductors and dielectrics. (It also has application in improving image detail in microscopy and in fluorescence-based imaging of biological samples.) Here's a snippet from their research, published in the August 2012 issue of the Journal of Optics:

In order to verify the state of polarization at the focal plane, laser induced periodic surface structures (LIPSS) are produced on stainless steel, imprinting the complex vectorial polarization structures and confirming the efficacy of the SLM in producing the desired polarization modes. Stainless steel plates of various thicknesses are micromachined with the radially and azimuthally polarized vortex beams and the resulting cut-outs are analyzed. The process efficiency and quality of each mode are compared with those of circular polarization. Radial polarization is confirmed to be the most efficient mode for machining high-aspect-ratio (depth/width > 3) channels thanks to its relatively higher absorptivity. Following our microprocessing tests, liquid-crystal SLMs emerged as a flexible off-the-shelf tool for producing radially and azimuthally polarized beams in existing ultrashort-pulse laser microprocessing systems.

About the Author

James Montgomery

Associate Editor

James manages editorial production for news (online and print) and newsletters, as well as the magazines' new product sections. Jim has 13 years’ experience in producing Web sites and e-mail newsletters in various technology markets for CNet, ZDNet, Digital City Boston/AOL, and KM World.