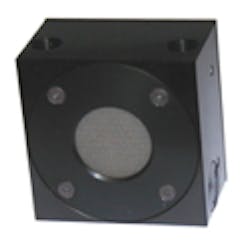

Axial thermal laser sensor, faster and for higher powers

Ophir Photonics, North Logan, UT, has unveiled a sensor incorporating a new thermopile design offering 20× faster response times and higher levels of power (20 kW) and energy (2000 J).

The Fast Axial OEM sensor applies the principle of axial heat flow in the direction of incident laser or light beams, instead of the usual radial flow sensor where heat flows from the center outwards. Heat flows through a thermopile deposited as a thin layer on the surface of the heat sink. Heat flows only a small distance axially into the substrate, resulting in significant improvements in response times and support for higher power levels.

As a result, the Fast Axial OEM sensor delivers response times up to 20 × better than other radial thermopile sensors, reaching 10%-90% response time in 50 ms, notes Gary Wagner, GM for Ophir Photonics (US). And the sensor can be configured to support very large beams -- up to 180 × 180 mm capable of measuring over 2000 J per pulse, and that configuration can also handle high powers over 20kW of average power.

High-speed, small-aperture versions of the Fast Axial OEM sensor can be used as internal monitors of high-power industrial lasers, where the fast response time enables better control of laser power. The smaller version can measure up to 150W.