Mitsubishi Electric develops laser micro glass processing technology

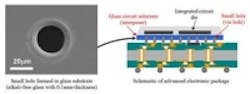

Tokyo, Japan – On February 14, Mitsubishi Electric Corp. announced it had developed patent-pending micro glass processing technologies that use a pulsed CO2 laser to drill the world's smallest holes, measuring just 25 microns in diameter in a glass substrate. The technology is expected to enhance the use of glass circuit substrates for the improved performance of electronic devices.

A far-infrared CO2 laser with a wavelength of about 10 microns is used to drill transparent glass, says Mitsubishi. Short microsecond laser pulses can reduce heating of the glass substrate during the laser drilling. Surface treatment technology is applied to suppress the over-enlargement of drilled holes.

Some 200 holes per second can be drilled using a high precision, high-speed galvo mirror to scan the laser beam. CO2 lasers, which can easily be geared to high power, are used widely in industry and offer vastly improved productivity compared to conventional ultraviolet laser oscillators characterized by high cost and limited light-harvesting properties.

Inquiries: http://www.mitsubishielectric.com/company/rd/research/labs/advanced_technology