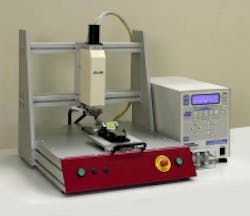

Miyachi Unitek offers desktop bonders with pulsed heat thermode technology

Miyachi Unitek Corporation, Morovia, Calif., a manufacturer of welding equipment and systems, announces the availability of its versatile series of desktop bonders, which are tabletop hot-bar reflow soldering systems capable of performing reflow soldering, heat seal bonding, and/or ACF bonding, hot bar bonding, and heat staking applications. The desktop bonders are useful for assembling medical devices, cellular phones, on-board computers, LCD monitors, laptops, and cockpit instrumentation and displays.

The desktop bonders use pneumatic bonding heads with the company’s Quick Connect Blocks and Thermo-plane Thermodes. The exclusive thermode design offers ultra-fast heating and cooling cycles, which minimize process times. Forced air-cooling after the heating process further speeds the total bonding process. The thermode is designed to maintain co-planarity and withstand deformation that tends to occur in some bonding processes. Another key design feature is the elimination of voltage drop as current flows from front-to-back instead of left-to-right, preventing damage to the parts when soldering.

The series includes a range of product handling features to tailor the bonder for use in particular applications, including left-right and front-rear slides, as well as rotary tables. Left-right and rotary models are ideal for higher throughput or higher volume applications, including production of cell phone parts. Models with in-out slides facilitate loading and unloading and visual alignment of parts, with or without a camera. The slide modules operate either manually or pneumatically and have an option for three-stop positions, which is specially designed for two bonding locations on a single printed circuit board (PCB), extremely useful for a flex to LCD and PCB bonding process. Additional options for the desktop series include optical alignment, Kapton feeder, water-cooling, and interposer modules, as well as customized product jigs.

Each of the desktop units in the series is connected to and powered by Miyachi Unitek’s powerful and flexible Uniflow3® power supply system for pulse-heated, selective soldering, conductive adhesive bonding and thermocompression bonding.