Ultra short pulse laser micromachining

Pelham, N.H. – Photomachining Inc., a job shop and custom systems manufacturer, has installed a Lumera Super Rapid 12 picosecond laser for customer applications.

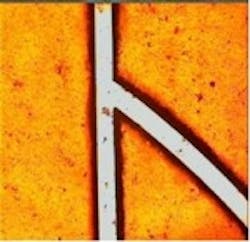

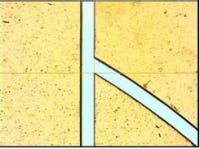

Ultra short pulse lasers are capable, if used correctly, of producing superior quality features on target. This can be seen from Figure 1, which shows a 30 ns pulse 355 nm laser compared to a 12 ps pulse 355 nm laser when machining KaptonTM. These photos are as-processed and taken directly from the laser system.

Figure 1. 355 nm, 30 ns pulse length

355 nm, 12 ps pulse length

More high resolution features using the Lumera laser are shown in Figure 2. These "hard" materials are all about 8 mils (200 microns) in thickness. The exit photos show clean and crisp edges without post laser processing.

Figure 2. Stainless steel

Copper

Alumina

The laser tool is set up with access to three wavelengths: 1064, 532, and 355 nm. Changeover between each wavelength is simple and quick. Each wavelength is delivered through a Scanlab galvo delivery system with a 100 mm f lens (other f lenses are available). The system has 24 inches of travel in each direction, assuring at least 12 inches under each of the heads. In addition, automated z-axis motion can be used to set part height or as a dynamic focus.

For more information on the work being done at Photomachining, contact Ron Schaeffer at [email protected].