ES Technology offers es PISTOL mobile laser marking system

ES Technology, Bordeaux, France, is to display the es PISTOL mobile laser marking system at the Laser World of Photonics exhibition taking place in Munich from May 23 to 26, 2011. Simple to implement and secure, the es PISTOL offers quality and speed of marking. Thanks to a wheels-mounted control unit and a compact and light laser head, the es PISTOL is an easy-to-move laser marking system.

Whether it is in a production unit or even from one company to another, it may now be practical to bring the laser up to the parts, which can sometimes be cumbersome or difficult to do. Moreover, the es PISTOL control unit includes a computer, marking software, and an operator interface available through a 10-inch touch screen. This allows marking of every kind of information, for example, texts, codes, and logos.

A full range of accessories (outline diode, removable housing, class 1 or class 4 workstation, Z axis, "on-the-fly" marking with specific housings, clamps for vertical mounting, fumes extraction, etc.) allows the user to readily adapt the system to many different situations.

Regarding safety, the portable laser system is designed to prevent the beam from shining out of the marking space, making this machine a class 1 laser system. The first level of safety is a laser housing (EN 207 standard). The second level is an inductive sensor, making it impossible to trigger the laser if there is no part to mark at the end of the system. In addition, a vacuum pump ensures that the system will stay firmly locked to the part during the marking process.

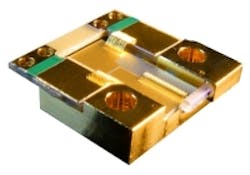

To ensure the best marking quality in spite of the system’s mobility, ES Technology chose to integrate, at the heart of the es PISTOL, the es CODE (20 W, marking field: 142 mm diameter, power supply : 350 W max) Ytterbium fiber laser technology and its high stability beam. As for the processing speed, it is secured by a galvanometer mirror's repositioning speed of 10 m/s.