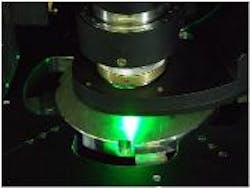

Laser helical drilling

Chemnitz, Germany – Laser drilling microholes in different materials has become a well-established process in the industrial sector, in therefore the production of structures with exactly defined geometries is gaining increasing importance. The process is typically accomplished by using special drilling optics, which deflect the laser beam by rotary motion to create the desired drilling geometry and size. Deficiencies in the beam profile play a minor role and can even be accounted for during laser processing. This way, drilling of high-quality holes with high aspect ratios can be produced.

In co-operation with Feinmess Dresden GmbH, a manufacturer of high precision motion systems for optical and mechanical systems, 3D-Micromac AG, a supplier of highly efficient laser micromachining systems, has developed a new concept of a helical drilling optic, which utilizes aerostatic instead of the usual mechanical bearings for all those components which are subject to continuous movement. The contactless bearing concept offers a reduction of friction losses while at same time an increase in guidance accuracies. This way, highly precise and reproducible laser drilled holes can be generated. Furthermore, wear and operating energy are decreased, which significantly improves the reliability and life cycle of the drilling optics.

Application areas include the automotive industry, aerospace engineering, and the textile industry, in which spinnerets are needed to achieve ever more complex shapes for the production of functional fibers.

The new drilling optics will be presented by 3D Micromac for the first time on occasion of Laser World of Photonics 2013 in Munich.