Cladding and welding heads

Gaggenau, Germany - Precitec has released two products: 1) its combination of the YC52 cladding head and its ScanTracker, and 2) the YW52 welding head.

Cladding head

Precitec has presented its new innovation, a combination of the YC52 cladding head and ScanTracker, which controls the track width adjusted to suit the application. The effective width of up to 18 mm can easily be optimized from seam to seam and configured for a stable process.

The weld seam width is just as wide as necessary and permits the highest possible welding speed for mid-range laser powers of 6 kW. All the requisite functions are fully integrated into the machining head, without the need for additional external sensors, cameras, or external positioning axes.

The ScanTracker is a good solution for applications involving differing weld seams or extensive retooling. The seam distribution is freely adjustable via an analog interface and requires no additional control. A synchronous laser power control is available to avoid intensity peaks at the reversal points.

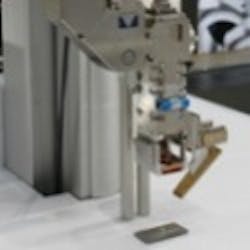

Welding head

At LASER 2013, Precitec debuted a YW52 laser welding head with the new cold wire feeding system from DINSE.

The new generation employs Push-Push technology with two fully decoupled propulsion units. The speed-controlled feed looks after the process, the torque-controlled feed limits the feed force. Regardless of torsion, length, and deflection of the fitting, a constant wire run is guaranteed. A newly developed feed system with 4 rollers allows the wire to be precisely conveyed and positioned through idealized force transfer. This optimizes the wire run and prevents wire breakage and slippage.

A process-oriented digital sensor mounted behind the feed monitors the wire run and captures data for extensive process monitoring. During monitoring, the sensor-supported, highly-precise wire positioning and conveying are automatically recorded with distance measurements the setting for the precise amount of the filler.

A wire brake is integrated as an additional component. This ensures a constant stick-out for the filler during the measuring process as well as during movements executed by the robot. This is required for precise weld seam detection.

The new system is rounded out by a control system expanded with a host of functionalities. An integrated touch-screen display with an intuitive menu guidance visualizes parameters, jobs, sensor-controlled monitoring units, language selection, error logs, and warning messages.