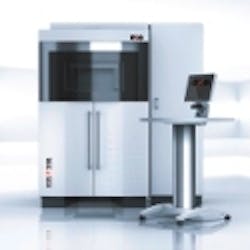

Production system for plastics

Frankfurt, Germany - EOS has recently introduced the EOS P 396 production system for the manufacture of plastic parts. The successor model to the EOSINT P 395 offers a multiplicity of features that comprehensively meet the growing demand for increased manufacturing efficiency, process stability, and building capacity. The latest CO2-laser generation and a completely revised temperature regulation enable double-digit increases in productivity. Global distribution of the EOS P 396 begins in April 2014.

The EOS P 396 combines building capacity of 340 x 340 x 600 mm with CO2-laser generation to maximize productivity. Reduction of secondary processing times is achieved by low wearing, high-speed recoater and integrated point pyrometer that continually measures temperature of powder surface for coating with high degree of precision.

With the unveiling of the new EOS P 396, the company has introduced a number of improvements. Dependent on the fill level and spectrum of parts, potential increases in manufacturing efficiency of up to 30 percent are possible. A reduction of the secondary processing times is achieved by a number of features, including a new point pyrometer and a low wearing, high speed recoater. Primary processing times are shortened thanks to the introduction of a new and significantly higher performance laser. The energy and material consumption of the system per manufactured component also has been further improved. This results in a reduction in operations costs and in an optimized product carbon footprint (per part). When the system is viewed in combination with highly economical materials such as PrimePart PLUS, then combined cost savings of some 30 percent per part are achievable in relation to the system's predecessor.

A newly integrated point pyrometer continually measures the temperature of the powder surface for coating with a high degree of precision. This enables secondary processing times to be further reduced leading to a corresponding increase in productivity. Furthermore, this feature forms the basis for a more stable regulation of the production process, thereby improving process reliability. With the availability of Release 3.7 of the EOS process-software (PSW) at the start of series production, the functional scope is once again expanded, and furthermore the Windows 7 operating system supported.

With the introduction of the EOS P 396, the plastic materials PA 2200 and PrimePart PLUS (PA 2221) will also be commercially available for this system from April 2014. Further materials will follow over several stages, until all of the powders approved for the predecessor system are available.