An operator can outperform an automated seam tracker

Burlington, Ontario, Canada - Xiris Automation Inc. claims automated seam tracking systems have not been able to match the accuracy that can be achieved when operators can view the seam. Operator visibility and judgment are still necessary elements of accuracy in seam tracking under certain conditions.

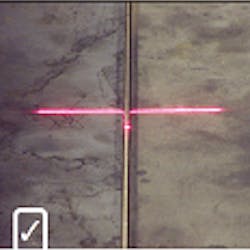

Why is this so? And how can operators obtain good seam visibility? Xiris suggests that those interested download its latest white paper — Why an Operator Can Still Outperform an Automated Laser Seam Tracker — and get the answers to these key questions. You can also learn: what conditions impact the accuracy of laser seam trackers, why an operator is a still a necessary element for accuracy, and how operators can use a weld view camera to get good visibility of seams.