Laser perforating systems double packaging speeds

Grimsby, North East Lincolnshire, UK - Ultimate Packaging Limited, a rapidly growing family business in the production of printed flexible packaging with annual turnover of 40 million pounds and a workforce of 280, is a valued supplier to many of the major supermarkets with a diverse selection of food and non-food brand names. Operating from a 100,000 square foot facility running 24/7, Ultimate is able to deliver a complete packaging service, from concept to finished pack, meeting the growing demands of its increasing customer base.

With up to 70% of the flexible packaging produced by the company delivered into the fresh produce and chilled food sectors, production of modified atmosphere packaging (MAP) has become a key part of the business. A dedicated technical team at Ultimate works with customers to define the unique laser perforation pattern required for each individual application, ensuring optimum performance and maximum shelf life. With the hole pattern established, it is essential that the systems used to produce these micro-sized apertures not only incorporate reliable methods of control and guarantee the size and shape of the holes being produced, but are capable of maintaining these essential attributes at the highest possible production speeds.

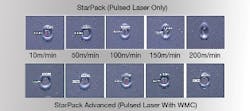

When a laser pulse hits fast-moving material, there can be instances where the quality of the resultant hole may not be quite as required. If web speed exceeds certain values, the holes can become visibly oval, and there may also be insufficient energy available within the pulse to completely perforate the material. In some cases, material produced at very high speed may not be of the accuracy required to allow the specified air exchange for the packaging and could therefore be deemed unusable. To achieve Ultimate's aim of increasing capacity, producing at higher speeds while guaranteeing consistent quality, the company turned to laser specialists Rofin-Baasel UK for a solution.

Rofin-Baasel has been active in the flexible packaging market for more than 10 years, with 200 plus customers already within the packaging industry. The system Ultimate Packaging installed is based on Rofin's high speed StarPack Web Direction System that incorporates a 300 W CO2 laser with 4 individual web movement compensation (WMC) heads. These heads control and optimize the perforation hole dimensions, ensuring consistency, which in turn results in maximum shelf life for fresh food products. In this configuration, the system can accommodate web widths of up to 1300 mm with production speeds in excess of 350 m per minute easily achievable, double that of the company's previous production systems.

A fully integrated in-process vision inspection system further enhances quality control and enables measurement data to be recorded and analyzed. The vision system captures images on-the-fly and checks hole diameter and percentage roundness, ensuring the perforated filmdelivered to the end user meets the exacting standards set by Ultimate Packaging to maintain product freshness and maximize shelf life.

This latest acquisition has been integrated seamlessly within Ultimate's film manufacturing facility to become a key part of the MAP production process. The new Rofin laser system also reinforces Ultimate's reputation as a company that seeks out and embraces the technologies that will allow it to continue its extraordinary product, process, and business development in the years to come.

Figure: Rofin's WMC controls and optimizes the perforation hole dimensions, ensuring consistency.