Lotus leaf inspires laser texturing method for creating self-cleaning metals

Taking their ideas from defense mechanisms found in plants such as the lotus leaf, a European project dubbed High Throughput Laser Texturing of Self-Cleaning and Antibacterial Surfaces (TresClean) will enable the production of self-cleaning sheet metal on an industrial scale. The technique will initially be used to create antibacterial surfaces for use in the food production industry, dramatically increasing productivity and reducing costs in factories that process biological food products such as milk, tomato sauce, and yogurt.

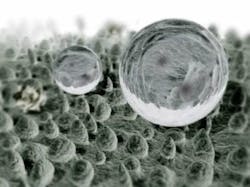

TresClean used high-power laser cutting devices to create a specifically tailored, rough micro-topography on sheet metal that mimics the surface of the Lotus leaf, causing liquids to "bounce off." This roughened surface creates miniature pockets of air that minimizes the contact area between the surface and a liquid.

"In the same way that lotus leaves keep themselves clean, without the need for cleaning products or chemicals, their jagged, rough surfaces enable water to stay as spherical droplets by preventing 'spreading,'" explains Luca Romoli, project coordinator of TresClean. "Bacteria do not get a chance to stick because the contact with the metal surface and the liquid is reduced by over 80%. We are looking at an antibacterial metal."

Metal surfaces are textured using high-average-power ultrafast lasers in combination with high-performance scanning heads by using an innovative beam delivery method, enabling movements of up to 200m/s. TresClean can achieve this surface texturation quickly by cutting 500cm2 areas in less than 30 minutes. In early 2015, production methods could make laser-etched metal at a rate of 1 sq. in. in 1 hour, whereas TresClean can produce 1000cm2 in the same period of time.

Romoli estimates that TresClean could have its products ready within 2 years.

For more information, please visit www.photonics21.org/index.php.