LZH researcher receives award for additive manufacturing technique with magnesium

The International Magnesium Association (Wauconda, IL) recognizes scientific-technical advances in magnesium-based technologies, products, and processes on an annual basis. At the 2016 World Magnesium Conference (held May 15-17 in Rome, Italy), the Award of Excellence in the Process category was awarded to Laser Zentrum Hannover (LZH; Hannover, Germany) researcher Dr. Matthias Gieseke for his work on additive manufacturing of magnesium components by selective laser melting (SLM).

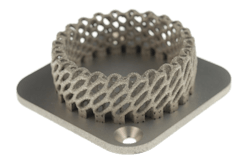

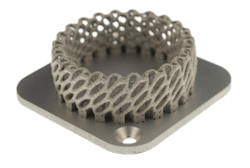

As a material, magnesium stands out for its very high strength, making it suitable for use in lightweight construction. What's more, magnesium is biocompatible and decomposes in the body: for these reasons, load-bearing and degradable stents and implants—for example, for replacement of bones—can be manufactured from this material. Additive manufacturing (also known as 3D printing) of components made of this metal is becoming increasingly important worldwide because of the high flexibility in terms of component geometry. Another advantage of SLM is the fast, cost-efficient manufacturing of prototypes and small series.

Because of the high reactivity of magnesium, the metal powder oxidizes quickly—even in an atmosphere of inert gas. The low vaporization temperature of magnesium leads to process emissions that pollute the processing chamber and have a negative effect on the process. In addition, undesired particles adhere to the surface.

To minimize these effects, Gieseke showed that magnesium's processability can be improved significantly when using very fine powders with a diameter of <20µm and alloys consisting of rare-earth elements, such as WE43, Elektron MAP+43, and Elektron MAP+21. Afterwards, he explains, a chemical post-treatment removes undesired particles and creates a smooth surface.

Gieseke's investigations show that the quality of SLM-manufactured magnesium components can be increased significantly. Appropriate laser melting systems are available on the market, so additive manufacturing of components made of magnesium or magnesium alloys with SLM can now be incorporated into an industrial process.

For more information, please visit www.lzh.de.