Fiber lasers allow dissimilar-materials welding, including copper to aluminum

Fiber lasers from SPI Lasers (Southhampton, Hampshire, England) have unique capabilities that ensure a wide range of high-quality micromachining processes—of particular interest is their ability to produce high-quality welds between dissimilar metals.

Nanosecond-pulsed lasers can apply welds in thin-section lap welding applications. The joints are often found in consumer electronics and batteries.

The challenge with welding dissimilar metals is that it often has issues with heat input and formation of brittle inter-metallic phases, but using fiber lasers reduces the heat input and the heat-affected zone to further reduce cycle time. Additional benefits of using fiber lasers are that they are able to produce accurate, controllable, consistent, and repeatable welds.

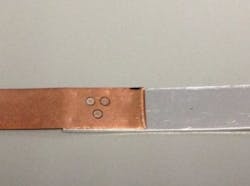

In a patented process, the company's redENERGY 70W EP-Z Laser creates three spot welds in approximately 1 s to produce an extremely strong hold between the copper and aluminum. The process is very quick and clean with no oxide layers and a low electrical resistance. This process will be detailed in a feature article in the January/February 2017 issue of Industrial Laser Solutions.

For more information, please visit www.spilasers.com.