Project develops laser source to precisely drill CFRP components

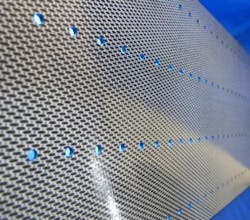

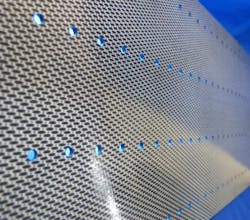

Composites such as carbon fiber-reinforced plastics (CFRPs) have a high potential for lightweight construction, and are now widely used in aviation. These materials have attractive properties, low weight, and high stability, but processing composites is quite complex using mechanical processes that can lead to high tool wear and quality problems.

In aviation, drilling of CFRP has compelling market potential because aircraft manufacturers produce increasing quantities with a high number of drilled holes for riveted and screwed joints. This requires reliable, fast, and cost-efficient processes to withstand competition, making laser beam drilling an ideal alternative to conventional processes.

In a project dubbed Laser Beam Drilling of Composites for Applications in Aviation (LABOKOMP), the partners will focus on the development of customized processing strategies using a new, high-pulse laser beam source.

To design a process that suits industrial needs, a tailor-made system, handling, and monitoring technique will be made available to users. With this, precise and dynamic handling and processing of high-quality serial components can be achieved.

In this project, Invent GmbH, KMS Technology Center, Trumpf Laser, and Premium Aerotec will develop automated clamping and positioning systems that include, among other things, an integrated vibration recognition and damping. Unlike conventional separation processes, a single clamping system can be used for all component variants. To provide a comprehensive entire process, the supply and exhaust of process gases and emissions as well as the cooling of the workpieces are optimized.

Laser Zentrum Hannover (LZH; Hannover, Germany)'s Composites Group will conduct material tests to minimize thermal stress on laser-drilled CFRP components, and at the same time increase efficiency through a tailor-made process control. In addition to manufacturing small components in large quantities, the process strategy may be transferred to assembly of large structures in the future.

This project is sponsored by the German Federal Ministry of Education and Research (BMBF; Bonn, Germany) within the scope of the KMU-innovativ: Photonik initiative for a duration of three years.