UPitt to develop fast computational modeling for additive manufacturing

As additive manufacturing becomes more commonplace, researchers and industry are seeking to mitigate the distortions and stresses inherent in fabricating these complex geometries. Researchers at the University of Pittsburgh's Swanson School of Engineering (Pennsylvania) and motion control systems maker Aerotech (also in Pittsburgh) received a $350,000 grant from the National Science Foundation (NSF) to address these design issues by developing new, fast computational methods for additive manufacturing.

The proposal, "Novel Computational Approaches to Address Key Design Optimization Issues for Metal Additive Manufacturing," is a three-year, $350,000 Grant Opportunities for Academic Liaison with Industry (GOALI) grant funded by the NSF's Division of Civil, Mechanical and Manufacturing Innovation (CMMI). The engineering team, based in the Swanson School's Department of Mechanical Engineering and Materials Science, includes associate professor and principal investigator (PI) Albert To and assistant professor Sangyeop Lee and adjunct associate professor Stephen Ludwick, both of whom are co-PIs. Aerotech will partner with the University of Pittsburgh by providing designs and evaluation. The group's research is an extension of previous funding from the Research for Advanced Manufacturing in Pennsylvania program (RAMP).

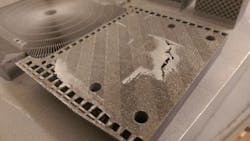

"The ability to create geometrically complex shapes through additive manufacturing is both a tremendous benefit and a significant challenge," To says. "Optimizing the design to compensate for residual distortion, residual stress, and post-machining requirements can take days or even months for these parts."

To mitigate these challenges, To and his group will first develop a simple yet accurate thermomechanics model to predict residual stress and distortion in an additively manufactured part. Next, they will develop a topology optimization method capable of generating designs with both free-form surfaces and machining-friendly surfaces. According to To, this will compensate for the geometric complexity and organic nature of additively manufactured parts, which contribute to their potential for distortion and post-machining problems. These approaches will then be developed and tested using real parts and design requirements provided by Aerotech.

Ludwick, who is also director of mechatronic research at Aerotech, expects that "the tools developed through this collaboration will allow us to produce the complex parts enabled by additive manufacturing with a minimum of trial-and-error and rework. This in turn allows us to design stiff and lightweight components in our high-speed motion systems, which are also used by other companies engaged in advanced manufacturing."

"By utilizing advanced mechanic theory, we hope to reduce design optimization of additive manufactured parts to minutes, thereby reducing the time of design life cycle," To says, adding that the US manufacturing base would widely adopt additive manufacturing and further improve the economic sustainability of the additive manufacturing process.

For more information, please visit www.engineering.pitt.edu.