Micromachining of metals is cheaper and faster with new laser technology

It is a fact of life that components are getting smaller and smaller, especially in the medical, automotive, and electronics markets. New micromachining technology, including advanced laser markers with superior beam quality, is being used to achieve results similar to traditional machining technologies, but cheaper, faster, and more flexibly. The fiber marker technology can be two to three times less expensive than standard technology.

High-volume manufacturers looking to meet miniaturization machining challenges while reducing costs can use the single-mode fiber laser marker to achieve excellent results on a range of materials, including steel, nickel, titanium, silicon, aluminum, and copper. The method should be considered by those thinking about updating or replacing electric discharge machining (EDM) equipment, as well as those who might otherwise normally turn to 532 and 355nm lasers when considering a new process.

Micromachining—seeing the result without seeing the details

Micromachining refers to making small features using such standard machining operations as drilling, cutting, scribing, and slotting—but on a smaller scale. There is actually no official scale for determining when an operation is micromachining, but a good rule of thumb is that the features cannot be seen "without one's glasses," or that you are "seeing the results without seeing the details." In other words, you might have no idea what was done to the material to get a particular effect. For example, if you drilled 50µm holes in a piece of copper, you would see light, but would not be able to see how big or small the holes were that are letting light through.

Fiber laser marker—the right tool for the job

In the hands of a skilled operator, recent advancements in the use of a fiber laser marker for micromachining can create desired features not normally associated with this equipment. The major benefit of this approach is that fiber laser markers are two to three times less expensive than standard equipment used for micromachining.

Working successfully at such a small scale requires the right tool as well as knowledge of how to use the tool to achieve the desired results, in terms of both quality and speed of material removal.

For example, Miyachi America recently introduced the LMF2000-SM single-mode fiber laser marker, which features unique parameters and control of those parameters that enables micromachining of fine detail dimensionally and at an excellent removal rate.

The laser marker features extremely high beam quality with M2 >1.3 to produce a focused optical spot size down to 20µm, making it particularly suited for scribing and cutting a wide variety of materials, including alumina, silicon, copper, and aluminum foils. In addition, the use of selectable pulse-width waveforms with different pulse widths and peak power characteristics enables tuning of the removal rate and quality of the feature surface.

This independent control of pulse width and peak power with pulse frequency offers clear advantages of control and process tunability compared to traditional Q-switched lasers that offer fixed pulse width/peak power settings as a function of Q-switch frequency. The scan head that rapidly moves the laser is also a key part of the system and needs to provide sufficiently high-speed movements with suitable repeatability and accuracy.

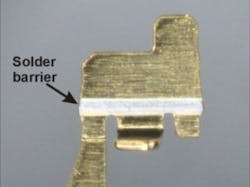

The fiber laser micromachining technology can be used for a wide variety of applications, such as selective plating removal for solder barrier, solar cell scribing and hole drilling, hole drilling of stainless steels for medical hypo tubes and fluid flow control systems, and cutting of sub-0.02in.-thick metals for fast part prototyping.

Comparing fiber markers with other micromachining technology

Single-mode fiber laser markers can be used as an alternative to more costly micromachining technologies, including sinker EDM equipment or 532 and 355nm Nd:YVO4 lasers.

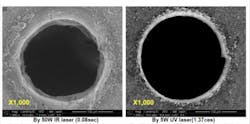

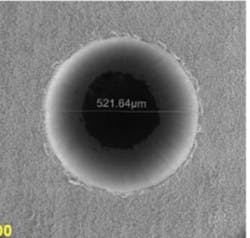

For example, in FIGURE 1, we see how the technology could be used as a replacement for sinker EDM machines. The picture on the left shows the drilling of a 150µm hole, ± 10µm in 200µm-thick steel, with no post processing. The minimal amount of debris and tight hole tolerance was achieved in 50% of the time taken by sinker EDM equipment.

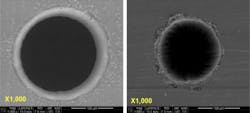

In addition, because the laser marker offers a working XY area, multiple parts can be completed in a single loading operation, as opposed to a one uploading on the sinker machine (unless an additional investment is made in motion equipment). This advantage makes the fiber laser marker return on investment (ROI) even more compelling. The fiber laser can also process difficult materials such as thin sheet material and foils—shown also in FIGURE 1 is a spiral with 100µm-wide elements machined in 50µm-thick copper foil.FIGURE 3 compares the quality of holes drilled with a 20W single fiber laser (left) and 5W 355nm laser (right) in 0.008in. stainless steel in the same processing time.

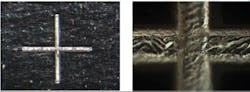

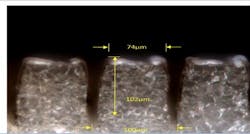

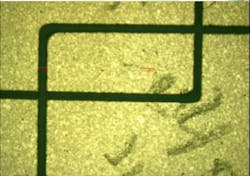

The finesse and machining control that is possible using the single-mode fiber laser is highlighted in FIGURE 4, in which the fiber laser marker was used to machine a 25µm-thick metal foil to a 13µm depth. The application was to provide a preferential failure point in a component. The channel width was 75µm and the depth variation over the entire area was ±1µm. (This equates to taking material that is 1/4 the width of a human hair and leaving only about 1/10 of a human hair after micromachining.)Single-mode fiber laser marker is a cost-effective micromachining workstation

The single-mode fiber laser marker can be a cost-effective micromachining workstation for drilling, cutting, scribing, and ablation for a variety of applications. And, of course, it can mark as well! This desktop mini machining center provides the benefits of dual- or multi-purposing to maximize ROI.

It must be noted that, in additional to having the right tool for the job, it is important to know how to use the tool efficiently and effectively. Miyachi America has developed a number of machining methods that enable the single-mode fiber laser to perform beyond its surface characteristics, while ensuring that the stability of the process is in line with a volume production process.

About the Author

Geoff Shannon, Ph.D.

Director Strategic Marketing for Precision Manufacturing, Coherent

Geoff Shannon, Ph.D., is Director Strategic Marketing for Precision Manufacturing at Coherent (Santa Clara, CA) and an Editorial Advisor to Industrial Laser Solutions. He previously served as Laser Technology Manager for Miyachi Unitek, specializing in the development of lasers and applications for existing and new markets. Shannon has a BEng in Mechanical Engineering and PhD in Laser Welding Technology from the University of Liverpool. His 20-year career in laser technology has centered around applications research and development and new product development of lasers and systems.