Laser shock processing enables improvements in wear resistance of metallic materials

Researchers at the Technical University of Madrid (Spain) have shown that laser shock processing for surface treatments of metallic materials improves their wear resistance, corrosion, and crack propagation properties. They have also proven that using the technique extends the useful life of stainless steels, aluminum alloys, and titanium. Because of these changes in surface properties, the technique has uses in material processing in the aeronautics, nuclear, automotive, and biomedical industries.

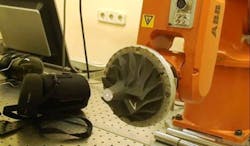

Laser shock processing (LSP) is a technique based on the deformation and generation of shock waves in metallic materials, enhancing the surface properties against wear, crack growth, and stress corrosion cracking. The researchers, led by Professor José Luis Ocaña in the the university's Laser Centre, used LSP to treat diverse components (turbines or elements used in artificial hips) to be able to enhance their wear resistance and extend their useful life.

In spite of LSP's availability in certain labs, practical developments at industrial levels still need to reach a sufficient level of industrial implementation. The Laser Centre is currently focused on enhancing LSP processes under different irradiation conditions, monitoring systems and process control for a straight transfer to industry. The researchers are also working on the design and development of numerical models that provide data of optimal values of the different process parameters.

For more information, please visit www.upm.es/internacional.