Laser 3D printing can biofabricate artificial blood vessels

Aachen, Germany - An interdisciplinary team of researchers, led by the Fraunhofer Institute for Laser Technology (ILT), has developed a laser 3D printing process for the production of artificial blood vessels out of innovative materials. They have created the foundation to cultivate a full-thickness skin model to a much greater layer thickness than previously possible.

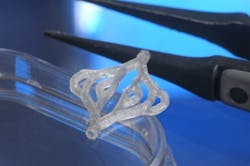

One of the biggest challenges the ArtiVasc 3D project faced was to develop the right material for the production of artificial blood vessels. For them to be used in the human body, these vessels must have the correct mechanical properties and biocompatibility as well as full processability. Indeed, endothelial cells and pericytes must be able to colonize the artificial blood vessels.

To generate these properties, the scientists combined the freeform methods of inkjet printing and stereolithography. With these combined processes, the researchers were able to achieve a very fine resolution for the construction of branched, porous blood vessels with layer thicknesses of about 20µm. The researchers used mathematical simulations to develop data for the construction of branched structures. This data should create the conditions so that branched structures can be generated, which allow uniform blood supply. The use of the acrylate-based synthetic polymer developed in the project permits the scientists to construct these optimized vessels with a pore diameter on the order of hundreds of microns. Compared to conventional methods, the ArtiVasc 3D process provides the general conditions to produce branched and biocompatible vessels in this size.

The results of ArtiVasc 3D are shaping the future. A toolbox has been developed that can respond flexibly to diverse materials, shapes, and sizes. These results can be viewed as a precursor to a fully automated process chain for the production of artificial blood vessels, and which can also be integrated into existing lines. Another highlight of the project is the successful breeding of adipose tissue in a novel bioreactor. The combination of the fatty tissue with an existing skin model allowed the production of a full-thickness skin model which has a thickness of up to 12mm.

The ArtiVasc 3D project has also laid the foundations for 3D tissue engineering. By using the principle of blood circulation with artificial blood vessels, medical engineers will be able to build larger structures such as whole organs in the future. For full skin cultured in vitro, there are a variety of applications: quick assistance for large-area skin injuries such as burns or after tumor resection as well as a replacement model that would make animal testing in the pharmaceutical industry unnecessary.

On October 28 and 29, 2015, the ArtiVasc 3D researchers will be presenting their results in detail prior to the final workshop at Fraunhofer ILT. For more information, please visit www.artivasc.eu.