New app allows laser processing simulation

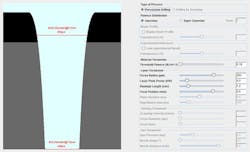

Simulation experts at the Fraunhofer Institute for Laser Technology (ILT; Aachen, Germany) have developed new software that requires much less in the way of resources, such that it can even run on tablets and smartphones. Individual parameters can be adjusted using sliders—the simulation result appears in an adjacent window and changes in real time.

This is made possible by an application-specific reduction of the computing models, a process in which certain simplifications are introduced depending on the respective application. Because these simplifications dramatically reduce the complexity of calculations, they produce a result much more quickly.

Conventional simulation programs deliver a complex representation of the processes involved in the interaction of laser beam and material. More than anything else, users are interested in things like how the conicity of a drill hole changes when parameters such as focal position or spot diameter are adjusted. The simplified simulation allows the influence of such parameters to be properly investigated, and the results match up with experimental data very well.

In contrast to earlier methods and to regular experiments, now the effects of changed parameters are displayed immediately. Changing individual parameters is virtually child’s play, and the results appear instantaneously in the adjacent window. This means that the simulation can be carried out directly at the laser machine. Time-intensive experiments are no longer required and setup processes can be completed much faster.

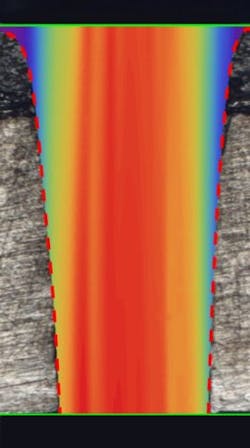

The high speed of simulation also opens up a range of entirely different options, such as metamodeling. Suitable for complex simulations with many parameters, metamodeling involves generating high-dimensional data sets with the parameters and several evaluation criteria for process and product quality. These sets can then be used to create individual process maps (hyper slices) that show the dependency of the results of individual parameter pairs. The quality of a result is always displayed using color coding so that optimum parameters are immediately visible.

This advanced simulation makes it possible to find global and local extreme values—for example, parameter sets for best and worst quality—through mathematical manipulation of the data sets. Such simultaneous optimization of multiple parameters is scarcely possible by experimental means. This means that new methods in manufacturing such as those of iterative design can be executed much faster.

The idea for the new software developed out of a particular order for a large customer. Further contracts have been concluded in the meantime, but the software is available for all customers. Depending on the planned application, it will be specially modified by the Fraunhofer ILT researchers to facilitate optimum results. The know-how resides in the skillful simplification of traditional models.

However, the software’s potential does not stop there; time-intensive calculations exist in many areas of industry. In the automotive sector, for example, the simulation of crash tests still uses up considerable computing capacity. Transferring the principle of reduced models promises substantial savings there, too.

For more information, please visit www.ilt.fraunhofer.de/en.html.