Aerotech helps Element Six upgrade laser machines to the latest standards

NICHOLAS RUBIES

Synthetic diamond materials maker Element Six has recently upgraded the controls for three of their laser cutting machines. The machines were initially equipped with third-party controllers running under the DOS operating system and were due for an upgrade to the latest control technologies.

There were several reasons to upgrade the laser cutting machines:

1. The I/O, which controls safety aspects of the machines, was embedded in the numerical control (NC) code of the machine, and this code was accessible by the laser operators. This required specific knowledge and discipline of the operators to ensure these functions would run correctly;

2. The existing components were difficult to service, making the machines unreliable in continuous operation; and

3. Code and code version management were difficult and cumbersome (DOS-OS), resulting in the machines not being part of the main company network. This could result in the use of incorrect versions of a program, leading to rejected products.

To overcome these issues, it was decided to upgrade the machines to the Aerotech Automation 3200 (A3200) controller already in use on other Element Six laser cutting machines. Standardizing on the A3200 platform ensured easy transfer and exchange of programs within the different Element Six production sites.

Machine design and implementation

To ensure that background I/O functions are independent of operator discipline and behavior, it was preferred to run these either as a separate task or on a separate dedicated programmable logic controller (PLC). Choosing a standalone PLC would have made communication between the A3200 and the PLC more complex. Therefore, it was decided to install MotionPAC, a soft PLC, for all of these functions.

The programmer at Element Six stated, "It was fairly easy to implement all I/O functionality in MotionPAC and add new functionality not previously available in our old machines. The clear user interface and functionality such as I/O mapping were of great help. I’m also convinced that other technical staff with basic skills in PLC programming can maintain the code. The use of the IEC61131 standard ensures that there is a wide base of experienced external engineers available to support major changes, if required."

MotionPAC offered Element Six the following advantages:

1. Using MotionPAC makes it much easier to generate NC code because all background functionality controlling the machine is performed by MotionPAC. This reduces the risk of programming errors in the NC code, which can lead to faulty products and unnecessary downtime of the laser cutting systems;

2. I/O functionality (even third-party vendor I/O) can be programmed using MotionPAC. This allows the same NC code program to be used on different machines without any modification; and

3. MotionPAC has improved machine safety and user friendliness for the operator. The new functionality makes the machines better at what they do.

Moreover, the A3200 controller offered its own advantages:

1. Upgrading brought the serviceability of the laser cutting machines back to the required level;

2. The A3200 platform makes exchange of knowledge and NC programs easy; and

3. The A3200 platform allows for future developments requiring more advanced motion patterns. These can be implemented without impacting on existing I/O, which is under MotionPAC control.

The machine using the A3200 controller and MotionPAC is shown below:

Examples

The examples that follow depict the benefits already mentioned.

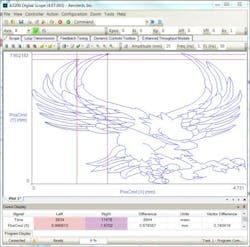

Generating and running NC (or G-code) in a motion engine that is integrated with a PLC separates the part program from the program running of the machine and the safety code. This allows programmers to apply the best tools to each part of the machine design. For instance, the NC code to generate an eagle is shown in the Motion Composer Suite (FIGURE 1). The NC code was generated from a CAD package while also including some more contemporary coding concepts such as defines for constants, Include for standard library functions and an ON/OFF signal to the laser shutter.

The I/O for the drive hardware and the fieldbus can all be defined or imported from a data definition file in the network tool and then connected to variables in the MotionPAC I/O Mapping tool (FIGURES 2 and 3, respectively). Errors and mismatches are shown continuously to assist in the programming and debugging process. The compiler runs in the background for MotionPAC and as errors are resolved, they immediately are reflected in the message updates.

Standard IEC61131-3 languages are available—Ladder, Structured Text, and Function Block programming. The network diagram is a free diagram that allows ladder and function blocks to be mixed on the same program (FIGURE 4). This minimizes the program size and makes programming easier.

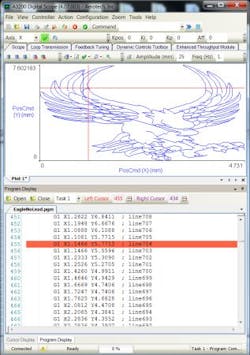

There is a built-in Scope (FIGURE 5) that provides extensive plotting and cursoring tools. FIGURE 5 shows the output of the NC program from FIGURE 1 that is plotted conditionally when the laser output is on in 2D. This helps to verify the part correctness. Signals can be overlaid, such as Position and Position Feedback, and the vector error can be easily determined from the Scope to be sure the part is in tolerance. The plot created can be conditional based on an I/O point, so only the interesting moves are shown—in this case, while the laser is on.

When a part is not meeting the tolerances required, usually the solution is to decrease the acceleration of the machine, thus slowing throughput of the entire process. A tool gives the user the ability to click on a move in the scope, and the line in the part program that made the move will be displayed (FIGURE 6). If this is the only move not meeting the required part tolerance, the acceleration during only this move can be lowered to meet specification and the acceleration during all the other moves can remain as-is—thus only marginally reducing throughput of the machine to meet the part tolerance specification.

As a full machine controller, many features are available for monitoring the health and status of all machine states, signals, and software variables (FIGURE 7).

NICHOLAS RUBIES([email protected]) is a control applications engineer at Aerotech (Tadley, Hampshire, England); www.aerotech.com.