Laser/robot welding cell ships

Newington, NH–Last month Integrated Robotics a full service integrator that provides turnkey, robot-based manufacturing solutions for fabrication processes (www.integrated-robotics.com)–shipped a custom-made 8kW laser/robot welding cell to a Nashua, NH, job shop serving the power generation industry. The cell comprises an 8kW TRUMPF TruDisk 8002 laser (the first to arrive in the U.S.), an ABB IRB 2400 robot, two 2000kg servo-axis coordinated positioning devices, and a Servo Robot real-time laser joint tracking system. A family of five or six parts will be processed for one customer on this system.

Traditionally the job shop used manual MIG or TIG welding, but this particular key contract would have required too many scarce skilled welders to accomplish the throughput required by the end customer. The multi-step MIG welding process included joint preparation, multi-pass welding, stress relief, and post-weld clean up.

An example part to be processed involves welding two side seams and the perimeter of the top and bottom of a rectangular box made from ½-in thick stainless steel. The application requires front to back full penetration welds. In the new laser/robot cell precision welds can be done with less preparation to the part at faster process speeds and less heat input.

The two-station cell enables parts and tooling weighing up to 4400 pounds to be crane loaded through eight-foot vertical door openings. One outside door and a middle divider door are closed during laser/robot welding. While welding is being performed on one side, the far-side door is open for the finished part to be removed and new part loaded. The cell is equipped with a Class 1 safety enclosure and the panel construction includes ventilation. Only one operator is required.

The system can be programmed using RobotStudio, ABB’s simulation and offline programming software. This enables programming to be done on a PC in the office without shutting production. Also, new tooling can be designed and built for new products without interrupting the current process. The system is built for quick tool change and clamping.

According to Christopher Andrews, Integrated Robotics’ president, most materials for the cell arrived here in late April, with the laser and robot arriving in May. It took the company about two months to complete the integration. Before taking receipt of the cell, the job shop expanded to a new second facility with additional machinery and equipment.

As soon as the 8kW laser/robot cell shipped, Integrated Robotics, which was founded in 2000 and currently has 22 employees, also moved to a new facility in Dover, NH, which increased its square footage by 50% and dramatically increased its capacity.

In addition to TRUMPF, Integrated Robotics also integrates Rofin-Sinar and IPG lasers. –LJB

Shipbuilder expands laser welding

Papenburg, Germany–Meyer Werft, a shipbuilder based here, will expand its welding capability with the addition of two disk lasers (TruDisk 10003s) and a CO2 laser (TruFlow 12000). The shipyard has been using CO2 lasers from TRUMPF to weld its metal plates for a number of years. The 10kW disk laser will also be used to weld I-joints.

Additionally the company will use the disk laser for the first time for laser hybrid welding in thick sheet metal. The shipyard will also benefit from beam guidance via laser light cable because the disk laser’s setup does not depend on location of the processing site. This increases production versatility and offers the shipbuilder advantages when processing the ever-growing size of sheet metal used in ships.

Lasers bear fruit for Cherry Corp.

Auerbach, Germany–Since the company’s incorporation by Walter L. Cherry in 1953, Cherry Electrical Corporation has grown to be recognized around the world for its range of innovative electrical products. Today, Cherry is the largest employer in this region with over 1,400 employees involved in the development and production of micro-switches, keyboards, components for the automobile industry, and controls for household appliances. In addition, subsidiaries in Wolfsbach and a factory near Klasterec in the Czech Republic, employ a further 700 personnel.

One key to the company’s success lies in its philosophy to embrace new technology. This can be demonstrated most effectively in the development of new manufacturing methods, for example, in the early use of laser technology.

Keyboard marking

Cherry started manufacturing computer keyboards in the 1980s and had quickly become a market leader. The individual keys however, originally injection-molded in two colors, proved to be too expensive for the emerging mass PC market.

In an effort to reduce manufacturing costs, the sublimation labeling method was introduced. This process, however, brought its own problems due to the ever-increasing number of country and function variants, as special sublimation paper had to be kept for the labeling of each individual character. These problems prompted a search for alternative production methods that would provide a more flexible and cost-effective way of labeling the keyboard keys.

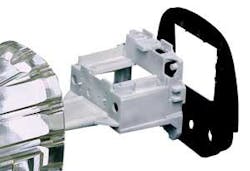

Using the correct parameters, Nd:YAG solid-state lasers generate a high-contrast mark through a color change in the material on a number of plastics. In contrast to printing, laser marking is indelible and anti-abrasive, even in cases of intensive use. With this process, the flexible deflection of the laser beam by galvo scanner heads provides a number of options for form and marking content. The target cycle time together with the size of the marking area, however, created a headache for Cherry. The processing area of a scanner head only covered half the width of the keyboard and mechanical repositioning of the keyboard or laser head was not possible due to the 20 seconds time available for each marking cycle.

Rofin-Sinar considered the application requirements closely before suggesting a solution based upon a laser, a beam splitter, and two deflection heads. The beam splitter would guide the laser beam through the scanner heads sequentially. Each head would then each mark half the keyboard in turn, within ten seconds. With the Cherry plant running a three-shift operation seven days a week, there was no scope for downtime due to problems with a new technology.

The prototype system fulfilled all expectations. Cherry then further optimized the composition of the plastics used in the manufacturing process to obtain the best possible marking results. Since then, laser marking has become established as the standard method for the production of keyboards.

Today at Cherry, up to three lasers mark a keyboard at once–two at the top and one at the bottom. In this way, the complicated adhesion of a label to the bottom of the keyboard is no longer necessary. If desired, monochrome manufacturer logos or text can also be generated at the same time. The entire marking procedure can be completed in less than 5 seconds.

On some of its five assembly lines, the company is increasingly producing value-added keyboards incorporating integrated barcode or chip card readers and fingerprint or RFID sensors. About 20 Rofin-Sinar second-generation diode-pumped lasers are currently in use in Auerbach. These lasers also permit bright white marking of black keyboards. Heinz Freiberger, head of keyboards at Cherry, emphasizes that there is almost no downtime. The lasers run reliably and malfunction-free around the clock as a key part in the production of the 10,000 keyboards that leave the factory each day.