Using lasers for decorative 3D texturing

Henrikki Pantsar, Reino Ruusu, Petri Laakso, VTT Technical Research Centre of Finland, and Michael Mårtenson, Oy Suomen EDM Ab

In order to utilize the texture mapping process with production quality and the least amount of texture distortions on 3D surfaces, the mapping process has to be well planned and executed

Numerous techniques have been used to create functional or decorative textures on components including techniques producing a random texture, such as electrical discharge machining/texturing or grinding. Other methods include laser ablation, electron beam texturing, chemical etching, and photochemical etching. The purpose of each of these techniques is to remove material from the surface of a component to form a texture or a pattern on the surface that will transform the visual appearance of the final product. The texture can be composed of geometrical shapes or patterns found in nature, such as leather, stone, wood, etc. In this respect, laser ablation is one of the best techniques because the process is reproducible, accurate, flexible, fully automated and uses no chemicals.

3D files that represent textured surfaces of components in detail can easily be hundreds of MBs in size. This leads to problems when transferring files from the CAD environment into the CAM system. The processing path generation can be time consuming and in worst cases takes almost as much time as the texturing itself. Another problem is the generation of a texture on a 3D surface, that is, how to create a texture that does not stretch around the corners and is projected correctly to the surface. A planar projection is easy to create on any object, but it appears correct only from one viewing angle. For example, it is impossible to create a pattern consisting of rectangular shapes on a spherical surface as the shapes will not appear rectangular on angled surfaces. The distortions can be optimized or minimized by correct texture mapping.

Surface decoration

The surface decoration starts with a CAD model of the surface that is to be decorated. Often the surface model has to be triangulated before a decorative image can be mapped on the surface. The surface triangulation can be made in the original CAD environment, but texture mapping adds some surface quality requirements that are not taken into account by the triangulation methods available in some CAD packages.

Successful application of texture maps for surface decoration requires a triangulated surface model with a certain degree of smoothness. The triangulation has to be dense enough and preferably fairly regular in shape. The triangulation algorithms in CAD applications usually generate triangulations that minimize the number of generated triangles and vertices. This is usually achieved by application of many very long or very flat triangles, as shown in Figure 1. Surface patches that are highly curved in one direction can also create a surface that is less smooth than the original model. For these reasons, it is usually better to perform the triangulation in some artistic modeling software.

Texture mapping

Texture mapping is a term that is used to describe both the actual process of decorating a 3D model’s surface and the process of fitting a set of 2D coordinates on a 3D surface. The result of texture mapping in the latter sense is a 3D surface model in which each 3D coordinate point is also associated with a 2D point in the texture space. These coordinates are usually called u and v, which is why it is sometimes called UV-mapping.

In some cases it is easier to directly map the original higher order surfaces. For this purpose, the surface patches are usually all converted to non-uniform rational B-splines (NURBS) or some other spline representation. NURBS are advantageous because they can be used to exactly represent conic sections, a fundamental part of primitive surface shapes like spheres (or ellipsoids), cylinders, cones, toruses, etc.

The problem with texture mapping complex spline-represented surfaces is that they are usually built of a set of trimmed surface patches that are rectangular patches trimmed with a set of curves. The same trimming curve is applied to surface patches on both sides of the curve to create an exact fit between the patches. This causes problems for texture mapping because there are no common control points between the two surfaces and it is difficult to get a continuous texture mapping across the trimmed boundary.

There are a lot of quality aspects in a texture mapping and these are somewhat dependent on the actual texture that is to be applied. For this reason, it might not always be possible to use the same mapping for all textures.

The texture mapping quality aspects can be divided into the amount of distortions, the number and locations of seams (locations where the texture coordinates are not continuous across a curve on the surface), and, for some textures, orientation-related aspects.

There are several different types of distortion that need to be taken into account. The image can be stretched or the texture size might be non-uniform. This is typical of a corner region, in which the 2D image must be stretched to fit over the corner, unless a seam is placed at the location.

The image can also be skewed so that the angle between its principal axes deviates from a straight angle. Theoretically this is just anisotropic stretching in an oblique angle. There can also be larger scale bending of the image, which is especially prevalent in images with perpendicular straight or grid-like features.

If the texture has very low entropy, i.e., it consists of mainly noise, almost any kind of distortion will go undetected. On the other hand, any distortion will be immediately visible on a very regular pattern with parallel elements. The level of disturbance caused by the distortions may also depend on the contents of the texture elements.

If the texture consists of randomly distributed symmetrical elements, the texture direction, and thus at least slow bending, of the image is not very noticeable even if the elements themselves are of high entropy. Some texture elements like faces, trees, some logos, etc., might have a basic direction that should be upheld at all cost by using carefully placed seams, whereas some textures might not tolerate seams at all. Some textures might tolerate high levels of anisotropic stretching in a certain direction, whereas some radially symmetric texture elements might look very bad if they are stretched anisotropically.

There are several automated mapping algorithms for triangulated surface mapping and several methods for automated optimization of texture mappings. One efficient method is least squares conformal mapping, which optimizes the mapping so that local angles are preserved as closely as possible.1 Some methods are based on relaxation. These methods take an initial texture mapping and use a relaxation operator that moves the coordinate points on the parametric space so that the shapes of the triangles move closer to the corresponding shapes in the world space.

Some software packages make it possible to project a higher order mapping from an auxiliary spline surface into the triangulated surface model. In all visual modeling tools, there is at least the possibility of projecting a simple primitive texture map, like a plane, a box, a cylinder, or a sphere onto the triangulated surface. For complex surfaces, this is usually only good as a starting point for some more advanced automated mapping algorithms.

Texturing methods

We have done experiments with two methods that can be used on existing laser machining software.

The first is based on 2.5D machining. This approach is the typical method for laser engraving. The triangulation is generated of the volume that is to be removed from the surface and the laser beam removes the material in thin layers according to the 3D file. The focal position is maintained at the surface by moving the z-axis after every couple of layers. Due to processing strategy, the surface quality is negatively affected by the machining layer boundaries and the boundaries are visible especially in smoother areas that are non-perpendicular to the beam.

The 3D model is mapped with texture coordinates and the texture image is selected. The resulting textured model must then be translated into a model that can be used for creating the tooling paths for the laser beam. For 2.5D scanning, the input geometry is usually an STL triangulation of the removed volume.

Here, we need an accurate representation of the surface with a focus on the distance of deviation from the target shape.

Algorithms that are used for refining displacement mapped surfaces for visualization purposes are usually based on recursive subdivision of the original triangulated surface. The subdivision is not necessarily based directly on the needs of the relief image. The image is only used for stopping the recursive subdivision when the triangle size is small enough. This is a good approach when there are limits on the triangle shapes. The subdivision can easily be arranged so that it retains the mesh quality of the original model.2, 3

However, some of these methods do not improve the model quality. To solve this, we have developed a new displacement mapping algorithm, which is reasonably fast, can equally guarantee the accurate reproduction of both the texture and the original surface model, and does not impose unnecessary requirements on the resulting triangulated surface. It is also completely insensitive to the form factors of the original surface triangles, making it very useful for handling STL models. The resulting model is further simplified by using an adaptation of the mesh simplification method of Hoppe et al.4, 5 The simplification method uses only distance as its criterion, resulting in an accurate, but optimally triangulated model of the decorated surface.

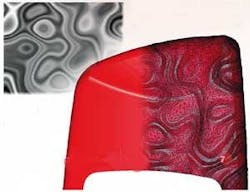

Figure 2 shows an example of a triangulation of a surface relief with a highly variable curvature. Triangle size and shape fit the surface requirements well. The grayscale bump map image, on which the displacement mapping is based, is shown in the top left corner.

The second method is based on surface-tracking tooling paths that are generated by projection from a pre-processed planar image onto the workpiece surface. For this method, a pre-warped representation of the decorative image is generated by using existing 3D visualization software.

Texture mapping on the 3D surface model is created in the normal way. The texture image is then rendered using the mapping so that a simple vertical projection of the rendered image produces the effects of the nonlinear mapping. In effect, the image is pre-warped to compensate against the distortions caused by the vertical projection.

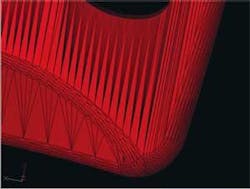

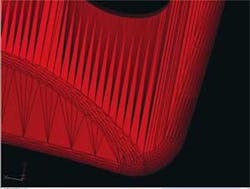

A high-resolution pre-warped image of the texture is generated by renderingit in orthogonal projection from above with no lighting. The planar projection is used for the actual laser processing. In short; the scanner, i.e. the x and y axes, are controlled according to the planar projection, as they would be in 2D processing. A high velocity z-axis is used during scanning to have the beam’s focal point follow the pre-machined surface. The pre-warped texture image is thus projected onto the model surface. This causes the distances of adjacent hatch lines to increase on oblique surfaces. According to our tests, this does not produce a noticeable effect on the surface quality, up to the machining hardware limit of a slope of 60 degrees. The planar projection of a pre-warped texture image projected onto a spherical surface is presented in Figure 3.

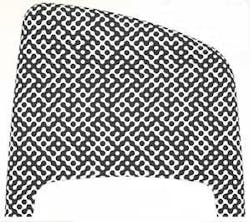

Unlike the results of the displacement mapping method, this method produces an embossing that is vertically aligned. On highly sloped surfaces, a relief that is either deep or very sharp may look strangely slanted. Use of a pre-warped image with higher than original resolution is used to compensate for the loss of resolution on the sloped regions. Figure 4 shows a part of the pre-warped texture that was used as an input for the decoration injection mold in Figure 5.

Laser texturing

Laser texturing is carried out by removing the texture volume by laser ablation. A typical laser setup for engraving and texturing is based on a 10–20W crystal laser and comprises a galvanometric scan head and optical and/or mechanical axes to control the z-movement. The focal spot diameter is defined by the collimated beam diameter and focal length of the focusing optic. The high quality beam of these lasers can be focused into a 15–40μm focal spot on the material surface, enabling ablation of fine features with high accuracy. Pulse repetition frequencies of 25–100kHz and scanning velocities ranging from a few hundred mms-1 up to 1000mms-1 are used. The used pulse width ranges from several nanoseconds up to several hundred nanoseconds.

These processing parameters are also typical for pulsed fiber lasers, which are available with a good, M2<2, beam quality and have been shown to be capable of high ablation quality. However, the Q-switched or MOPA fiber lasers do not share the same first pulse control capabilities as crystal lasers. Therefore, they experienced beam delays, ramp-up times or first pulse overshooting, which can limit their use in some engraving applications. Some of these lasers have features, such as pulse width adjustment, that can be used to improve surface quality.7 Overall, pulsed fiber lasers can provide a highly cost effective solution for texturing, but crystal lasers still seem to control the market in the most demanding applications.

In the example presented in this article, the texture was ablated using a 15W Nd:YVO4 laser and a 3D work station with three optical and three mechanical axes. The high quality and accuracy of the texturing process and texture mapping can be seen in Figure 5. The mold was used to injection mold cellular phone covers with a textured surface (see Figure 6).

After engraving the texture, the surface quality can be improved by controlled re-melting of the surface. Re-melting can improve the optical properties of the surface, facilitate part detachment from the mold, or just add more decorative features to the product. The surface can be re-melted using laser parameters below the ablation threshold, by either switching the Q-switch of a crystal laser off,6 or stretching the pulse on a MOPA fiber laser to limit the peak power.7 When this is carried out in an inert gas atmosphere, an oxide-free glossy surface can be created. The method is a good alternative for treating complex or small geometries that are troublesome to polish manually. An EDM processed surface with laser re-melted rectangular areas is shown in Figure 7.

Conclusions

A laser is a versatile tool for 3D texturing. It can be used not only for direct marking and decoration of products, but also for decorative texturing of injection molds, from which the texture is copied to the surface of the final product. The primary process for laser texturing of molds is ablation or engraving. Ablation itself is a well-known technique, but in order to utilize the process with production quality and the least amount of texture distortions on 3D surfaces, the mapping process has to be well planned and executed.

As presented in this paper, with correct tools and know-how, the texture mapping process can be done easily from any bump-map image. File transfer to the laser processing unit does not normally cause problems, whether the files are transferred as 3D files or pre-warped textures. Additional design features can be added to the mold/product by selective remelting of the surface and improving the surface quality, or altering the surface shape. Overall, surface texturing adds value to plastic products with very low cost per component.

Dr. Henrikki Pantsar, Reino Ruusu, and Petri Laakso were with VTT Technical Research Centre of Finland, Lappeenranta, Finland at the time of the work. Michael Mårtenson is with Oy Suomen EDM Ab, Porvoo, Finland. Dr. Pantsar is now with Fraunhofer USA Inc. Center for Laser Technology in Plymouth, MI. For more information, please contact him at [email protected].

References

- B. Lévy, S. Petitjean, N. Ray, J. Maillot, “Least Squares Conformal Maps for Automatic Texture Atlas Generation,” ACM Trans. Graph., Vol. 21, No. 3, 2002, pp. 362–371.

- K. Moule, M.D. McCool, “Efficient Bounded Adaptive Tessellation of Displacement Maps,” Proc. Graphics Interface, May 2002, Galgary, Alberta, pp. 171–180.

- X.C. Wang, J. Maillot, E. Fiume, V. Ng-Thow-Hing, A. Woo, S. Bakshi, “Feature-based Displacement Mapping,” Proceedings of the Eurographics Workshop on Rendering Techniques 2000, Springer-Verlag, 2000, pp. 257.

- H. Hoppe, “Progressive Meshes,” SIGGRAPH ‘96: Proceedings of the 23rd Annual Conference on Computer Graphics and Interactive Techniques, ACM Press, 1996, p. 99.

- H. Hoppe, T. DeRose, T. Duchamp, J. McDonald, W. Stuetzle, “Mesh Optimization,” SIGGRAPH ‘93: Proceedings of the 20th Annual Conference on Computer Graphics and Interactive Techniques, ACM Press, 1993, p. 19.

- H. Pantsar, R. Ruusu, P. Laakso, A. Jansson, “Advances in 3D Laser Processing in Mold Technology,” 25th International Congress on Applications of Lasers and Electro-Optics, Oct. 20-Nov. 2, 2006, Scottsdale, AZ.

- H. Pantsar, H. Herfurth, S. Heinemann, T Lauterborn, “Micromachining Using Flexible Pulsed Fiber Lasers, Proc. 11th NOLAMP Conference on Laser Processing of Materials, Aug. 20-22, 2007, Acta Universitatis Lappeenrantaensis 273, Lappeenranta, Finland, pp. 262–270.