Meeting the challenge

Rochester Hills, MI—Project leaders for Chrysler’s new “retro” Dodge Challenger were determined to thoroughly test the vehicle’s components and systems’ performance while constructing prototype vehicles to accurately gauge market response. The problem was many prototype shops were not ready, willing, or able to invest time, labor, and dollars to develop concept tooling, processes, and prototype construction for a limited production schedule of 5000 to 6000 vehicles per year.

Included among the parts needed to complete vehicle models were both the front and rear wrap around fascias (see photo) measuring 72 x 28 in (with grill cutouts, lighting openings, side markers, and options for single- and dual-exhaust packages), the rear left and right tail lamp assemblies, and the central light bar spanning the rear deck.

Chrysler had been offered an unacceptable four-month delivery schedule. The design and engineering team at 3-Dimensional Services (www.3dimensional.com) and group member Urgent Plastic Services (both located in Rochester Hills) reviewed the parts required and, offering to deliver prototypes in eight weeks, received an order. They immediately began to develop both injection mold tooling for the tail lamps and light bar systems—consisting of nearly 80 individual components—and RIM-style molds, measuring approximately eight feet long by four feet deep and weighing up to 2400 pounds along with inserts and variations for the fascias.

Within the eight-week time period, the first of the front and rear fascia assemblies and the entire 125 sets of the tail lamp and light bar appliqué were delivered. The project included adhesive assembly of the lighting components, replicated reflex lens construction, wiring harnesses, air dams, grill components, lamps, and side markers, plus all mounting brackets and supports. Chrysler stylists and engineers were able to test the components for fit, function, and aesthetics and to run simulated assembly procedures. The early prototype completions provided a chance to gauge consumer reactions and response to the final, critical design elements.

3-Dimensional utilized a five-axis laser cutting machine to trim out openings for light packages, while SLA (stereolithography apparatus) positive models of the fascias were employed to help create the negative mold patterns. These models were formed from multiple parts that were then pieced together to form a single fascia replica.

The design of the pattern for the rear fascia had to accommodate the various engine and exhaust options that would be available. These options required major tool adaptations, multiple inserts, and significant design complexities.

To minimize delays and operations waiting for injection mold tools to be completed, the companies used E-Z Cut aluminum alloy for the mold tooling, which holds up well in low to medium volume molding applications.

Major sections of the fascia patterns were constructed from and shaped using Ren Shape 450, a modeling material of cured polyurethane specially formulated to be an easy-to-machine, dimensionally stable material, ideal for use with CNC machining equipment. This was instrumental in producing the smooth, A-Class visible surfaces for both the front and rear fascia sections.

To finalize the total affect of the lighting systems and tail lamp assemblies, 3-Dimensional Services Group associates, using their own in-house injection molding equipment, including an 850-ton unit and a 500-ton system, developed insert molding tools that generated a virtual no-line transition from the clear backup lighting lens and the stop/turn signal red acrylic material.

3-Dimensional Services Group provided the parts Chrysler needed in about half the time they were being quoted by other shops. And the whole package they developed, including tooling designs, process standards, accessory packages and assembly data, helped the automaker beat its competition to the showroom floor with an exciting new vehicle.

Plastic laser sintering service extended

Letchworth, UK—Ogle Models has introduced a flame-retardant plastic to the range of materials that it uses to produce components for customers. Designated PA 2210 FR, the powder is produced by EOS (www.eos.info) for use in its laser sintering machines. Ogle operates three such machines, two of which were bought in June 2008: an EOSINT P730 with 700 x 380 x 580mm build volume and a 200 x 500 x 330mm capacity FORMIGA P 100.

Ogle believes it is one of the first rapid prototyping/rapid machining bureaus in Europe to run the fire-resistant materials in its machines. By the end of July, the company had produced two sets of parts for the cabin and fuel tank of an aircraft in quantities ranging from 50 to 200.

The material was designed to meet the flammability, smoke, and toxicity standards of the civil aerospace industry. Manufacturers like Boeing, Dassault, Embraer, and others have successfully tested the new material. The powder typically qualifies for “flying hardware” with wall thicknesses down to 2mm.

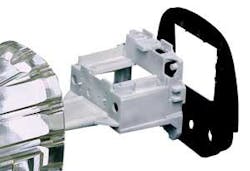

Series production of laser sintered plastic components is becoming the norm at Ogle. A good example is the manufacture of parts in batches of several hundred for a thermal imaging camera used in search-and-rescue work (see photo). From a CAD model supplied by the customer, laser sintering is used to make the chassis that supports the thermal imaging screen and the electronics. No hard tooling is required, so any alteration in design is easily accommodated without incurrnig additional expense.

The process of additive layer manufacturing by laser sintering is fully self-supporting, enabling parts to be built within other parts and with complex geometries that could not be realized any other way. These attributes lower the cost of production and offer freedom of design. Moreover, the resulting components are strong and rigid enough to be used in places where they may be subjected to mechanical and thermal stress.

David Bennion, Ogle sales and marketing director, described a project carried out for

a rally team. Prototype under-bonnet parts previously machined from aluminum and composites, specifically for the air inlet catch tank and head breather, were replaced by laser sintered, aluminum-filled nylon, reducing both the weight and cost of the new car. The integrity of the parts was maintained during seven days of rigorous endurance and reliability tests in Europe, during which the car clocked up to 870 miles/1400 km.

Ceramic substrate machining

South Lyon, Michigan—Fiber lasers are a new technology for scribing, drilling, and cutting of ceramic substrates in an industry dominated by CO2 laser technology. Synchron Laser Services (www.synchronlaser.com) has developed a process that it claims is the first major improvement in accuracy and precision combined with very high throughput in laser scribing of ceramics since the early 1970s.

The high brightness and small focused spot size of the fiber laser, compared to the lower beam quality and 10x longer wavelength of CO2 lasers, achieves the fine cut and tolerance requirements demanded by today’s applications. With an easily removable proprietary coating, Synchron has developed a process capability to replace 500W CO2 lasers with 200W fiber lasers from SPI Laser for this application.

An example of a high-tolerance application is in the rapidly growing market for LED video screens. Having made an impact in the outdoor advertising and entertainment display market over the past few years, the number of full-color indoor displays being installed in shopping centers, supermarkets, convention centers, airports, railway stations, and sports arenas to entertain, market products, or provide useful information to the public is increasing significantly. Moreover, the trend in the indoor display industry is moving towards smaller screen sizes, which in turn require a smaller pixel pitch for better screen resolution and higher contrast.

Displays that are viewed at close distances require high brightness, high contrast, and low heat dissipation to avoid the need for cooling fans. Mounting the LEDs on ceramic substrates provides the heat sinking capabilities that enable the LEDs to be driven at the high drive currents required to achieve this performance.

The current market shortage of helium—which makes up ~80% of the CO2 laser’s gas mix—has caused its price to almost double in the past few months with many customers being placed on restricted supply schedules. The advantages of the fiber laser, including low heat affected zone (HAZ) and high position and machining tolerances, together with the significant cost-of-ownership savings both in terms of overall energy efficiency and maintenance costs compared to those of flowing CO2 lasers make a compelling business proposition.

Contact Brett Moon ([email protected]) at Synchron Laser Services for more information.