Bee in your bonnet?

Würzburg, Germany – Since 2006, bee expert Professor Dr. Jürgen Tautz has been developing HOBOS (Honey Bee Online Studies) as a novel and interactive teaching concept that involves tagging the honeybees with codes that only a laser can make. A preliminary stage in June 2009 made it possible for school classes from nine countries to delve into a real honeybee colony via the Internet. These countries included Germany, US, China, Luxembourg, Northern Ireland, Italy, South Africa, Switzerland, and Jordan.

Project leader Tautz, supporter Hartmut Vierle and several freelancers have conceived a specialized beehive equipped with sensors, measuring devices, and thermographic cameras. ILS saw a promotion piece (see photo) that featured a bee with an attached 2D bar code. We were intrigued that each honeybee is identified for tracking by this tag so we asked Mr. Vierle how the tags were made.

How it works

“We started with RFID tags, but because of the high costs of each RFID tag that we used before, we weren’t able to equip a large number of bees with individual serial numbers,” said Vierle. “We looked for an alternative and found 2D barcodes to be suitable for our experimental setups. The barcode only has to store the individual number of the bee, but must be very tough — mechanically as well as optically because the bees constantly rub against each other in the hive. The barcode must tolerate a high grade of staining and still retain its information. A laser is the only way of creating these tiny tags (1.5 x 1.5 mm) with the desired sharpness and contrast necessary for vision system reading.”

Sheets of tags are received from sponsors, KBA METRONIC and TESA. Each tag is cut out and attached, using shellac glue, manually to the bees, which are caught at the hive entrance and then cooled down in a refrigerator, thus immobilizing them. A small syringe filled with shellac glue is used to put a drop of glue on the honeybee‘s thorax, between its wings and then, using forceps, a tag is pressed onto this drop of glue. After a while, the bee awakes and the solvent in the glue (ethanol) is gone.

Its importance

By observing this living superorganism important for many ecosystems and agriculture, different aspects of the honeybee’s behavior, ecology and agriculture can be understood, says the project. One can also get a grasp on ecology and agriculture at a global level. An intelligent treatment of the biosphere, HOBOS says, is necessary for the future of mankind.

The Internet portal HOBOS will be extended as an educational portal for schools and universities during the next few years. All data are accessible online and are stored on a long-term basis.

This project is pursued with low intensity as a part of the high-tech HOBOS hive (http://www.hobos.de/) and it will be included so that everyone with access to the Web can watch the events in real-time as well as work on scientific projects with the recorded videos and measurement readings. The BEEgroup is looking for sponsors to help with new technologies, and, in return, it will provide a platform for product placement and so on.

For more information, contact: Hartmut Vierle at the BEEgroup, Bienenstation der Universität Würzburg at [email protected].

Diode laser-assisted carbon fiber tape placement

Mülheim-Kärlich, Germany, and Santa Clara, CA — Diode lasers are revolutionizing the tape placement and winding technology of fiber-reinforced plastics. Their local heating and accurate temperature control replaces large autoclaves enabling one-step processing of thermoplastics. Advanced fiber placement technology with diode lasers is currently used by the aerospace automotive and off-shore industry.

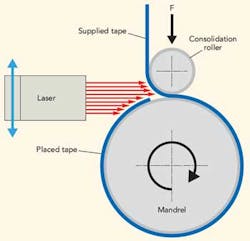

Laserline GmbH (www.laserline.de) has tackled the task to develop an efficient process for tape winding and tape placement with the power of a diode laser. Increasingly, items such as aircraft parts, pressure vessels, seals, and pipes that have traditionally been made of steel or aluminium are being replaced by ones made out of carbon fiber reinforced thermoplastics (CFRP). The use of CFRP improves the mechanical properties of the product and can create a weight savings of up to 70 percent. Laserline’s customer — AFPT GmbH — manufactures products from tapes wound or placed on a mandrel or mould (see FIGURE). In a controlled process, the diode laser efficiently heats and melts the tape material in the joint area.

AFPT GmbH built a tape placement head mounted on a robot to place CFRP tape on the 3D preform. Working in close cooperation with the customer, Laserline developed special homogenizing optics to heat the CFRP strips as they are placed. These optics produce a rectangular laser focus with a very uniform energy distribution. A coaxial multi-point temperature control regulates the laser power to ensure a safe heating of the material and keeps it below the decomposition temperature.

Since 2009, diode lasers have been used in the production of CFRP components. Special homogenizing optics, 3 kW of laser power, and high process efficiency result in tape layering speeds of several meters per minute. The small footprint of the fiber-coupled diode laser module, coupled with its high efficiency, allowed the customer to build a robust, compact, class-1 welding cell, suitable for transport on roads.

Laserline, a manufacturer of diode lasers for material processing, has more than 1200 systems being used in industrial applications such as key-hole and heat conduction welding of steel and aluminium, cladding/coating and repair welding, brazing, as well as hardening/heat treatment.

AFPT recently entered the market with the newly developed tape placement process. At its development center in Dörth, Germany, AFPT develops and produces tape placement systems based on a modular principle.

For more information, contact Andre Eltze at [email protected].

More Industrial Laser Solutions Current Issue Articles

More Industrial Laser Solutions Archives Issue Articles