Femtosecond laser machines leather for automotive without visible damage

Jenoptik (Jena, Germany) has been developing femtosecond lasers since 2006 and recently started using them in the automotive and consumer sector to machine genuine leather. The lasers' advantage is that their ultrashort pulses induce no visible thermal damage in leather, as opposed to longer pulses.

Passenger airbags in cars are hidden behind interior linings made of synthetic material or, particularly in premium cars, of genuine leather (FIGURE 1). In case of a crash, to ensure reliable bursting of the airbag through the cover lining, the lining needs predetermined break lines scribed into its rear side, which for aesthetic reasons cannot be visible from the passenger's side (FIGURE 2).

For synthetic airbag linings, a patented Jenoptik CO2 laser scribing method for making invisible break lines has been a market leader for several years. This laser-based method has proven to be more economical and precise than alternative mechanical techniques of scribing with knives. However, the transfer of the laser process to genuine leather requires some modifications. The reason is that the thermal ablation process with a CO2 laser leads inevitably to a swelling of the leather around the scribe, which lets the scribe appear as a visible ridge on the front side.

The solution is in the introduction of femtosecond pulsed laser radiation. With such radiation, the swelling of the leather can be completely prevented. The shorter the pulses are, the less the material swells. Jenoptik has demonstrated a patented process that produces scribes in genuine leather as invisible as in synthetics at a pulse width of around 500fs. Moreover, accelerated lifetime tests by automotive customers with femtosecond-scribed leather lining showed that the break lines remain invisible over the required periods of time under all environmental conditions.

Based on these results, Jenoptik developed and introduced the VOTAN A laser perforation machine powered by a 10W femtosecond disk laser (FIGURE 3) for scribing genuine and synthetic leather airbag covers. The process fully meets the demanding requirements of the automotive industry and for premium products in the consumer industry, including process speed.

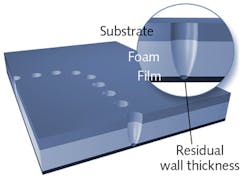

In this system, via galvanometer scanner, the femtosecond beam makes highly precise but non-piercing cuts at high speeds into 1- to 2mm-thick leather without any traces of carbonization (FIGURE 4). Such low heat affect is possible because of the non-thermal ablation mechanism in the femtosecond pulse width regime. In addition, the multi-megawatt peak powers induce nonlinear absorption effects that strongly reduce the dependency on material-specific linear absorption coefficients. Therefore, all different leather types and colors can be scribed with nearly the same process parameters.

The scribe depth is controlled by infrared sensors that measure the transmission through the leather and stop the scribing as soon as the transmission exceeds a certain threshold. The typical unevenness of leather is taken into account by the multi-pass scribe process, as the machine memorizes finished positions on the break line and spares them at subsequent passes.

The JenLas femto 10 thin disk allows efficient cooling and perfect thermal control of the active thin disk medium, which enables excellent beam quality close to the theoretical optimum as well as higher pulse energies than typical fiber laser concepts.

This article was provided by Markus Roehner on behalf of Jenoptik, www.jenoptik.com.