Industrial fiber beam delivery enhances ultrafast laser machining

Fiber-optic beam delivery has been the key enabler for wide industrial application of high-power solid-state continuous-wave (CW) lasers. Until recently, fiber-optic beam delivery could not be used with ultrafast lasers. Now, microstructured hollow-core fibers make it possible to confine the laser light inside a small hollow core, and transmit pico- and femtosecond pulses of high energy with excellent beam quality. Packaged into a rugged laser-light cable, this is likely the start of a new era in laser beam delivery (FIGURE 1).

Ultrafast lasers exhibit a growing number of applications, as they allow processing of practically any kind of material with unrivaled precision. Exact control of the pulse in time, space, and shape is required to attain the optimum output from an ultrafast laser, and establish the technology in industrial applications. A key component in a laser processing system is the optical interface between the laser source and the application—the beam delivery system. Its main purpose is to simply transport the laser beam as efficiently and undisturbed as possible from the laser source to the desired spot on the workpiece. However, additional functionality is increasingly demanded to enhance the laser beam in shaping it spatially and temporally.

In the 1990s, the introduction of fiber-based beam delivery systems for CW diode and solid-state lasers was a major breakthrough for industrial laser applications, and is a de facto standard for CW applications with up to multi-kilowatt laser power. Similar impacts can be expected if a fiber beam delivery in ultrafast laser applications can be realized.

Beam delivery of ultrafast pulses

Free-space beam delivery is employed today for the emerging class of ultrafast lasers with pulse durations below a few picoseconds and pulse energies high enough for material processing. These mirror-based systems can be very alignment-sensitive (particularly for longer distances) and may suffer from contamination with dust and particles. They also introduce a large number of optical components into the beam path, which are potential sources of beam degradation. Additionally, a stable and well-engineered support structure is required and typically, the laser source has to be located in close proximity to the application. This usually involves a lot of cost and effort in the overall system design.

The lack of standardized beam delivery solutions further leads to individual beam delivery solutions and hinders a wide application of ultrafast lasers in industrial applications. Adaptation of a new laser source requires additional alignment effort and, finally, significant cost. Fiber-based beam delivery systems cannot be found today, as classical fibers are no longer suitable. They suffer from dispersion, making the pulses longer; they exhibit insufficient damage threshold; and, for high-energy pulses, nonlinear effects such as self-focusing, stimulated Brillouin scattering, or Raman scattering take over and destroy the fiber material or pulse profile. As a consequence, ultrafast pulses for industrial applications cannot be transmitted using conventional glass fibers.

New fibers confine light in a hollow core

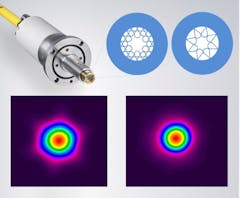

Microstructured hollow-core fibers (MHCFs; FIGURE 2) support light propagation mostly inside a hollow core (e.g., in gas or vacuum), enabling high power handling and drastically reduced nonlinear effects. Such fibers are an evolution of photonic crystal fibers, which were first developed in the 1990s by Russell, Knight, and Birks at Bath University (England). Since then, other types of microstructured fibers have been developed and have demonstrated their potential for high-power ultrafast laser beam delivery. These have a core size comparable to step-index fibers (for single-mode operation) and confine the light inside an irregularity of the crystal-like structure—the core. The core region of a single-mode fiber can be much larger as with step-index fibers, allowing even higher damage thresholds. For this class of fiber, more than 99% of the laser light can be guided inside the hollow core, greatly improving maximum permissible laser pulse energy up to levels in the milljoule regime—well beyond many material processing applications.With proper integration into an industrial beam delivery system, ultrafast laser pulses with multi-100W and multi-100μJ can be reliably transmitted with excellent beam quality. A beam delivery system making use of these fibers greatly enhances industrial application by increasing robustness, separating laser source and application, and distributing laser energy to multiple workstations and robot-based applications.

Because of the low dispersion on the order of a few picoseconds/kilometers/nanometers, hollow-core fibers are particularly suitable for pulses down to the femtosecond regime. For wavelengths around 1μm, attenuation values between 30 and 70dB/km or approximately 1% per meter are possible over the 900–1100nm spectral range.

From hollow-core fibers to ultrafast beam delivery systems

A fiber-based beam delivery system consists of a beam launching system, a laser-light cable with integrated fiber, and a processing head. To match the output of the laser source to the fiber, a coupling unit—or beam launching system (BLS; FIGURE 3)—is required to adapt the size of the beam exiting the laser source and focus it to exactly the required spot size at the fiber tip. This will maximize transmission efficiency and increase the beam quality exiting the fiber. Positioning needs to be accurate to a fraction of the spot size, typically in the few-micron regime-putting high demand on mechanical interfaces and stability. The optical system is diffraction-limited and, depending on the laser beam quality of the source, delivers a Gaussian intensity distribution at the focal position. However, fulfilling the requirements on mechanical stability and imaging quality is known state-of-the-art technology for high-power CW laser beam launching.The optical fiber itself is well protected from the environment. A rugged outer conduit designed to withstand millions of bendings in robot or gantry applications assures reliable operation in daily industrial use. Mechanical stress needs to be kept to a minimum, even under rough operation and particles. Dust or moisture should not enter the fiber, as these will reduce performance and may cause fiber damage.

The connector design features a window to create a sealed environment and be far enough away to minimize laser damage to the coatings and bulk material of the window. The enclosed volume can be filled with clean air or any other gas, and may be pressurized or vacuumed. The fiber itself is mechanically held into position with good thermal contact. Water cooling is optional to reduce thermal effects at higher power levels. Dedicated alignment of the fiber tip with respect to the connector interfaces guarantees high repeatability when changing laser-light cables. Reconnecting the same cable requires virtually no realignment of the laser focus.

A flange-type mounting supports high-precision interfaces and is quickly connected. At the same time, the O-ring seal offers a safe protection when used in typical industrial manufacturing conditions. In addition to the optical functionality, the laser-light cable can feature security functions known from high-power laser-light cables. The protective conduit will protect from exiting laser light in case of fiber breakage. Also, fiber break and proper connection of cable and coupling unit are monitored according to industry standards.

Application to industrial ultrafast lasers

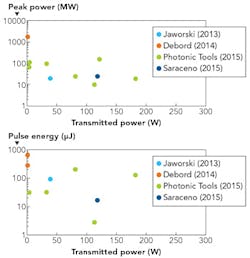

Performance evaluation of the fiber beam delivery with industrial ultrafast laser systems that range from 3 to 200W of average power, 300fs to 10ps, and pulse energies between 3 and 250μJ reveals the full potential of the new technology. With proper coupling using a dedicated beam launching system, the laser-light cable can operate over a very wide range of ultrafast laser parameters. Pulse durations in the femtosecond regime can be transmitted, as well as average powers of multi-100W and pulse energies of multi-100μJ with typical transmission above 90% for a 3- to 5m-long cable. Coupling efficiency is constant, even for different power levels indicating negligible focus shift with respect to the fiber end face, enabling applications with fast power modulation. Physical limitations are only reached for high pulse energies that can damage the fiber end face, overheating because of fiber losses at high average powers and pulse degradation because of nonlinear effects at high peak powers.

With optional water cooling and evacuation of the laser-light cable connector, very high average powers and high peak powers can be handled (FIGURE 4) with experimental values from field testing.Given the correct beam launching, the delivered beam quality at the output of the laser-light cable is also very high—M2 of 1.3 is generally achieved. FIGURE 2 shows the near- and far-field images of the laser beam transmitted by a typical microstructured fiber. Both have M2 of 1.3 and very symmetric far-field profiles.

Conclusion

Fiber-based beam delivery systems once paved the way for industrial application of diode and solid-state lasers in material processing. For ultrafast lasers, similar solutions are now available and have the potential to similarly impact ultrafast laser applications.

The biggest advantage will be a far simpler system integration facilitated by the laser-light cable, enabling the laser to be located away from the application and the movement of the processing machine—there will not be a need for a heavy support structure. A delicate-free space beam delivery system, a simpler exchange, and service of components are additional benefits. These technical advantages go along with major reduction of the total cost of ownership for the overall laser system installation.

Application results show that excellent beam quality, pulse duration, and power of a laser can be preserved over distances of several-meter-long fibers integrated in a beam delivery system. Both transmission and beam quality are robust to mechanical loads, thanks to a rugged design of interfaces. Bending and movement of the laser-light cables within typical limits of bending diameters do not change power transmission and only have a small effect on the location of the intensity profile. For ultrafast laser applications between 900 and 1100nm, a laser-light cable can easily transmit hundreds of watts in average power and hundreds of microjoules in pulse energy.

About the Author

Björn Wedel

Founder and CEO, PT Photonic Tools

Björn Wedel is founder and CEO of PT Photonic Tools (Berlin, Germany).

Max Funck

Head of Research and Development, PT Photonic Tools

Max Funck is head of research and development at PT Photonic Tools (Berlin, Germany).