Variable focus tunable lens technology makes laser marking flexible

Lenses enable continuous tuning of the focal length

JOERG WERTLI and DAVID STADLER

Laser marking systems have experienced strong growth over recent years—a trend that is expected to continue. A strong driver in the market is the need to identify parts in automatic manufacturing processes. These identification codes are typically laser-marked on the parts with standard laser marking systems using 1064nm fiber laser sources, usually 10mm X-Y scanners and an f-theta lens for field flattening. With production processes becoming more flexible, laser marking systems have to follow this trend and provide the flexibility to not only mark a code on a two-dimensional (2D) field, but also on different heights or even on curved or complex surfaces. This requires the integration of a z-axis in addition to the x-y scanner. Focus-tunable lenses provide a very capable solution to achieve a large z-range, enabling the building of compact, light scan heads with the flexibility to quickly mark parts of various sizes.

For example, the working principle of Optotune's EL-10-42-OF lens is based on a shape-changing spherical lens, which allows for continuous tuning of the focal length. Tunable lenses can be integrated in laser marking systems, including an f-theta lens for field flattening—typically referred to as 2.5D marking. In this case, the z-axis is only used to jump between different levels.

Another approach is to set up a three-dimensional (3D) laser marking system without an f-theta lens. In this case, the z-axis is used for field flattening as well as the focus adjustments to jump between different levels or follow the contour of curved or complex surfaces. In this article, we look at the possibilities, advantages, and disadvantages of both approaches.

2.5D laser marking

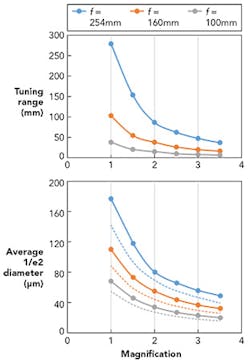

Setting up a laser marking system with a z-axis to jump between different levels and an f-theta lens for field flattening is a straightforward process. Typical z-axis solutions vary the focus around infinity. In combination with the f-theta lens, this results in a symmetric z-range around the working distance of the chosen f-theta lens. The z-axis can simply be placed between the laser head and the x-y scanner. Because focus-tunable lenses are very compact and light, they easily retrofit between the laser head and the x-y scanner of most setups. Despite the small form factor, tunable lenses provide a large z-range of 100mm in combination with an f-theta lens with f = 160mm. The z-range increases with the larger focal length of the f-theta lens. An additional beam expander allows for adjusting the z-range as desired, thereby optimizing the performance for the required specifications. FIGURE 1 shows the decreasing z-range and spot size with the increasing magnification factor of the beam expander.

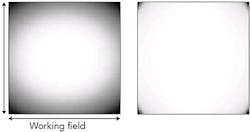

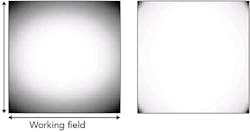

However, when optimizing a 2.5D laser marking system, it is important to note that the tunable lens, like every other z-axis solution, leads to a slightly converging or diverging laser beam. Yet for optimal operation, the f-theta lens requires a collimated input beam—therefore, the achievable performance in terms of spot size on the working field at different z-positions is not the same for all f-theta lenses. FIGURE 2 shows how the spot size on the working field varies for two different types of f-theta lenses—grayscale encodes the spot size, black means larger spot size, and white means smaller spot size. The right image has a very homogeneous distribution over the whole working field, whereas the left image shows an increased spot size at the corners. This effect potentially reduces the size of the usable working field, and it is therefore recommended to integrate higher-quality f-theta lenses.

3D laser marking

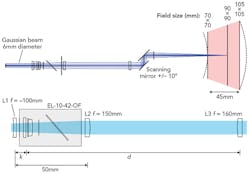

When building a laser marking system with additional flexibility regarding the z-axis, the ultimate goal is to fully replace the f-theta lens. The resulting dynamic 3-axis scan system provides several advantages: because of the absence of the f-theta lens, which is more cost-efficient, such a system provides a significantly larger scan field. Also, simpler optics results in better optical performance, so the spot size is more homogeneously distributed over the marking field. The additional focusing optics to create a spot on the workpiece allows for adjusting the z-range, spot size, and scan field to the specific requirements of a laser marking system. The tunable lens stays at a fixed position and changes its spherical shape to tune the focus, in contrast to a physically moving glass lens. As a consequence, it is possible to design a reasonably simple optical setup that keeps the spot size constant over the full z-range. Such a system with a z-range of 45mm is illustrated in FIGURE 3.

From the controller point of view, 3D laser marking poses some challenges. A 3-axis scan system requires dynamic focusing for each position in the 3D marking volume. Therefore, it is crucial to note the different dynamic behavior of the 3-axis system—the resonance frequency of the tunable lens is typically 200 Hz, which is lower compared to the x-y scanner. Independent of the technology used, this has to be taken into account on the hardware and software side.

Outlook

Future developments will proceed along two lines. Based on the existing product, an integrated 3-axis scan head based on focus-tunable lenses would take full advantage of the compact form factor and large z-range for a wide range of applications. Currently, focus-tunable lenses are only available for applications with 1064 or 532nm lasers. Future product developments will address this limitation to cover further commonly used wavelengths from the ultraviolet up to the infrared range.

JOERG WERTLI([email protected]) is senior sales manager and Dr. DAVID STADLERis application engineer, both at Optotune, Dietikon, Switzerland; www.optotune.com.