Sweet success

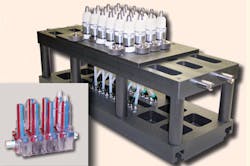

Manchester, NH -- Freed's, a division of Maplehurst Bakeries (Brownsburg, IN), is one of the largest cupcake makers in the U.S., supplying in-store bakeries with both iced and un-iced cupcakes in a variety of sizes, flavors, and colors. Recently, their two-color icing tool, a complicated mechanism that applies precisely the right amount, pattern, and color of icing to the products on their main automated production line, was nearing the end of its useful lifespan. Obtaining a replacement tool was a problem as the manufacturer had discontinued this particular line and was no longer servicing it. For a solution, the company turned to 3-Dimensional Services Group www.3dimensional.com of Rochester Hills, MI, a rapid prototyping firm that specializes in the design, engineering, and analysis, in-house tool construction, and complete build of first-off parts and low- to medium-volume production runs.

There were no available CAD drawings for this tool, so 3-Dimensional Services reverse-engineered the tool—disassembling it, dimensioning the components, and drawing them in order to create a CAD file for use by one of its stereolithography (SLA) machines that produces a solid working model of the design, critical for hands-on review of form, fit, and function. This process was accomplished in a week.

The model of the design was inspected and approved by Freed's, and 3-Dimensional Services rapidly built and delivered the replacement tool.

This was not the end of the story because during this project, Freed's revealed that they weren't completely satisfied with the tool's existing design. For one thing, this two-color icing tool was too heavy to be used on any but Freed's most heavy-duty machine. The company would have liked the flexibility to employ it on other machines as well. It was also a very complex mechanism so periodic maintenance was time-consuming, and it sometimes had problems with icing leakage.

The 3-Dimensional Services team also wasn't completely satisfied because the reverse-engineering process had revealed several areas where the design could be improved. After explaining this to Freed's, the team got the green light to try and create an improved design.

For starters, there were the hoses that conducted the icing from the mixing vats to ports in the nozzles, with two hoses feeding each port. Long exposure to the strong, food-industry-strength cleaners used on the machine left the hoses brittle and susceptible to breakage; replacing them, though, was difficult and time-consuming. Each time a hose broke, Freed's had to remove all of the hoses that stood in the way of the failed hose, including removing each hose's clamps. Since hose failure was not a rare occurrence, this was a major source of downtime.

3-Dimensional Services responded by cutting a runner system into the aluminum plate of the tool's interior to facilitate the flow of icing, eliminating 24 of the tool's 48 hoses, slashing in half the potential number of hose breakage incidents. They also replaced the conventional hose clamps with quick-connect fittings that were faster and easier to attach and reattach. A new hose arrangement enabled maintenance personnel to change a broken hose without having to remove good hoses in order to get to it. This combination boosted uptime and productive capacity by over 50% and also led to weight savings.

"Additionally, pockets cut in the tool's aluminum plates got rid of excess aluminum that wasn't needed for its structural integrity,” says Jerry Eversole, Senior Designer/CAD Operations Manager for 3-Dimensional Services. In addition, with the aid of some design changes, two rods could adequately perform certain valve functions, eliminating two stainless steel rods and further reducing weight. As a result, the new two-color icing tool can now be used on Freed's other, lighter machines if the need arises, giving the company the flexibility it had long desired but never had.

The problem of icing leakage or "color bleed” was corrected by tapering the top of the plastic cylinders in the icing heads that channel the icing, providing a tight seal when the screws are tightened. The end result was a lighter, more flexible, and more productive icing tool that was more energy efficient, with higher quality and reduced material usage.

— Submitted by 3-Dimensional Services, www.3dimensional.com

Laser melting of inserts for mold tools

Bremen, Germany — Plastic injection molding and die casting are key processes for cost-effective mass production. The especially complex shaped tools are very expensive to produce. To ensure high productivity, tool durability has to be high. The choice of materials is made on the basis of a trade-off: the need to be machineable but also to provide high wear resistance.

A typical material used in mold construction is the steel 1.2343 (AISI grade H11), which needs to withstand different types of wear. Tool wear can be increased dramatically on spots of injection where respective inserts are used. To generate wear-resistant inserts, the selective laser melting process was chosen as it offers to produce near net shape parts out of a variety of materials. The highly wear-resistant tungsten-carbide cobalt alloys WC-Co 83/17 and WC-Co 88/12 were chosen to be generated on steel substrates. A major challenge was the determination of process parameters and exposition sequence strategies to meet desired densities and avoid cracking. The influence of process parameters and weld trajectories on the density was investigated. It was found that the key to achieve densities of >95% through the complete specimens was the combination of comparatively low scanning speed, large beam diameter, and checkerboard-shaped weld trajectories. In the studies, it could be shown that the single boards were to be made with overlap. A tool insert is shown in FIGURE 1. These inserts fulfilled the requirements for being brazed to the tool steel 1.2343. The brazing process was successfully developed and applied by the project partner ISAF of TU Clausthal.

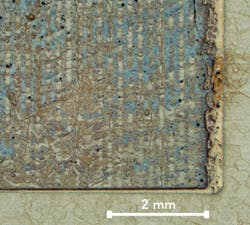

An example of a WC-Co specimen brazed to steel with a copper paste brazing solder is shown in FIGURE 2. The wire-eroded lower side as well as the unprocessed right side of the SLM part are joined, without defects, to the steel. Infiltrated areas appear in light color within the WC-Co. Now, the parameters and scanning strategies determined can be used for generating more complexly shaped inserts. Together with our partners from research and industry, the complete process chain of generating and joining wear-protective inserts could be realized. The German Federal Ministry of Economy and Technology represented by the AiF funded this project 16.492 N "Generieren und Fügen von SLM-Bauteilen aus Hartmetall”.

— M.Sc. Henry Köhler, BIAS, www.bias.de

More Industrial Laser Solutions Current Issue Articles

More Industrial Laser Solutions Archives Issue Articles