Laser welding of white polymer components

The color degree of complexity is finally complete

by Sibylle Glaser

Laser welding of polymers is now a well-established method for joining plastic parts. The process is a precise and contactless technology that releases no particles, such as those experienced in ultrasonic welding or solvents in the gluing process, and traces of these processes on the surface of the components are avoided. Therefore, the laser is an interesting method for joining electronics or medical devices. However as laser welding of polymers gained a broader market, the appearance (color and surface) of the joining parts became more important.

In the beginning of laser welding polymers, from the 1980s through today, the color of choice in non-visable parts was mostly black. However, as thermoplastic polymers began being used in a wide variety of applications of everyday life, color became more important in polymer applications.

Color and colorants

Color is an individual perception, which is stimulated by light and received by the human eye in the wavelength range of 400 to 700 nm. Depending on the light source, the reflected wavelengths can vary and, therefore, the visible color can also be different. That phenomenon is called metamerism.

For the coloration of polymers, pigments and dyes are used. Pigments can be of organic or inorganic structure and are insoluble in plastics during processing as well as in the end product. Organic pigments normally have a high chroma (color strength) but less opacity than inorganic pigments, which on the other hand show a lower chroma. Primary particle sizes are generally < 1 µm for organic pigments and > 1 µm for inorganic pigments. Dyes are organic molecules and dissolve in the medium, therefore, no particles are visible and the transparency of the material remains unchanged. A homogenous distribution and dispersion of the colorants in the polymer matrix is necessary to achieve a good welding process. By using twin-screw extruders, colorants and/or additives can be evenly incorporated into the polymer matrix [1,2].

Influence of colorants

When using lasers with transparent and absorbing parts, there is always a link between the color in the visible spectrum and the function in the near infrared (NIR), which has to be considered during the development of the corresponding color formulations. In general, the optical properties of colorants are only documented in the wavelength range of visible light of 400–700 nm. But beside creating the visible color, colorants can influence the optical properties in the NIR. In some cases, their behavior in the NIR is different than in the visible. Therefore, the relevant optical properties (transmission, reflection, absorption, and scattering) of each colorant in the NIR have to be analyzed. With knowledge of these data, color formulations for nearly all colors for laser transparent parts as well as laser absorbing parts can be developed.

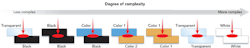

Degree of complexity

Concerning colors, a degree of complexity was created (FIGURE 1) due to the fact that general statements of feasibility cannot be made.

As mentioned, when laser welding of polymers began, carbon black was used as an absorber. With that type of absorber, only dark and black absorbing colors are possible. To change the appearance of the laser transparent part, laser transparent black color formulations were developed soon after. Today for nearly all types of polymers laser, transparent black products are available. Later on, the industry required more colorful solutions. Adapted absorber systems with neutral colors were developed and within limits bright color combinations became possible. Due to the fact that different colorants have to be used in the laser transparent and laser absorbing material, metamerism is always of concern when parts with the same color are welded. By using nearly transparent absorbers, it is possible to avoid metamerism as the identical color formulations can be applied in both parts.

One of the most difficult color combinations in laser welding is transparent on transparent. Several transparent absorber products are commercially available, but a slight color (blue, green, yellow, light brown) depending on the absorption maximum cannot be avoided. Also due to their absorption, maximum specific laser wavelengths for welding are required and have to be selected for each product [1,3].

A new approach is the welding of transparent/transparent without absorber additives by using new laser wavelengths. In this process, the optical properties, especially the intrinisic absorption of the polymers, are utilized and by optimizing the optical setup of the laser system, a sufficient welding seam can be achieved [4].

Laser welding of white parts

The combination with the highest complexity is the welding of white on white. The challenge in this combination is the white color itself. In the visible range, the light is completely reflected on the surface of a part so that the human eye identifies the color as white. This also applies for the laser light in the NIR. Consequently, the pigment loading is restricted in the laser transparent part and a compromise between color (opacity) and function (transmission) has to be found. The result is usually a translucent color with a low opacity (FIGURE 3).

Due to advances in the development of NIR absorbers with neutral colors, there is improvement in white laser absorbing color formulations with good absorption properties Titanium dioxide (TiO2) is the most used white colorant. It is an inorganic pigment with a high opacity and the best coloring properties, usually used for white, opaque, and light colors. The typical concentrations of TiO2 in plastics coloring are in the range of 0.1 up to 3.0 wt-%, depending on color and polymer type. In laser transparent parts using standard lasers with wavelengths in the range between 0.8 and 1 µm, the maximum pigment loading for a stable welding process is below 0.2 wt-%. With the development of new lasers with wavelengths between 1.5 and 2 µm, the possibilities for white parts were extended. For example, the degree of transmission of a white sample part increased from 27% to 41% by using a wavelength of 1.5 µm instead of 0.8 µm, and the degree of reflection is reduced from 85% to 57%. A reduction in scattering, which is directly related to the welding process, could also be detected. That enables pigment loadings higher than 1 wt-%, which can result in more opaque colors.

In FIGURE 2, the different white laser transparent parts for lasers in the wavelength range of 0.8–1 µm and 1.5–2 µm are shown. For better recognition, the absorbing parts are in black. The upper laser transparent white sample is loaded with the maximum concentration possible for a stable welding process using a wavelength of 0.8 µm. The sample below is welded using a wavelength of 1.5 µm, and the opacity has significantly increased.

For the absorbing material, similar results can be obtained. Due to a lower degree of reflection, the absorption of the laser light is enhanced and therefore, less laser power is needed and the absorber concentration can be reduced. This enables a stable welding process with competitive process conditions of opaque white parts. Possible applications can be found in consumer goods, household applications, or in medical device components.

Summary

By using laser systems at different wavelengths, the number of color combinations for polymer joining can be increased significantly. The degree of complexity has been rationalized, and the process can be broadened due to the possibility not only of the combination white/white but also by pastel colors like light blue or light pink, etc. Knowledge about spectral data of the materials (colorants, polymers, and absorbers) is still essential for a successful welding process. ✺

Acknowledgments

The author gratefully acknowledges the support for this work through the EU funded 7th framework project: "Extending the process limits of laser polymer welding with high-brilliance beam sources" (Polybright). Grant agreement number: NMP2-LA-2009-228725.

References

- S. Glaser, Colorants and special additives for laser welding, Joining Plastics Conference Proceedings 2006, Paper 23, ISBN 1 87957 570 6.

- M. Bastian, Einfärben von Kunststoffen, Carl Hanser Verlag München, 2010, ISBN 978-3-446-41848-6.

- U.A. Russek, Laser welding of polymers, Sueddeutscher Verlag onpact GmbH München, 2009.

- A. Rösner, A. Olowinsky, "Laser welding of polymers," Industrial Laser Solutions, January/February 2013, pp. 23-31.

Dr. Sibylle Glaser([email protected]) is the head of R&D at Treffert GmbH & Co.KG - Bingen, Germany.

More Industrial Laser Solutions Current Issue Articles

More Industrial Laser Solutions Archives Issue Articles