Remote laser cutting of near-net-shape & fiber-reinforced parts

ANNETT KLOTZBACH and ANDREAS FÜRST

The present trend within the transportation industry requires resource-efficient designs. In addition to novel engine concepts, a basic approach is reducing the mass of the main parts of the vehicle. Thus, fiber-reinforced polymers are finding their way into the structures of aircraft and automobiles [1, 2].

Reducing weight by using lightweight textile structures can be done in the mass production market only if the price is acceptable. As a result of a September 2012 market study, the following key strategies were forecast by the German industry:

- Material hybridization by the use of different material compositions within one part and produced within one production step (use of short, long, and endless fibers, combined with metal segments);

- Process improvements by using process simulations and automated productions; and

- Use of near-net-shape fiber-reinforced parts to reduce material consumption [3].

Working on these topics, the use of conventional material treatment techniques like water jet cutting or mechanical treatment will be much more ambitious. New solutions like laser treatment are needed to process efficient wear- and force-free multidimensional parts in high volume applications.

In metal cutting and welding, the laser as an expensive processing tool is found in many application fields, where a high productivity tool has to treat complex structures in a flexible manner. To transfer the laser use to fiber-reinforced parts seems obvious, but is not always possible for most material compositions at an acceptable quality because of thermo-optical behavior.

Thermo-optical property differences

In general, polymer materials do not absorb laser beam energy between the near-UV and near-IR range. In this area, molecule or electron excitation enables volume absorption and consequentially a heating of the material. The optical properties are dependent on the material composition in composite materials like carbon or glass fiber reinforced with polymer matrices. Only a few additives can change the material behavior from nontreatable to treatable. To understand the interaction mechanism, a wide range of material combinations have to be analyzed.

Therefore, different experimental methods were used to evaluate the optical characteristics of certain specimens. Near-IR and IR spectroscopy are rapid and nondestructive methods to characterize reflectance and transmittance. Direct irradiation experiments with low laser power can document the heating up of the probes by thermal cameras. As the result of these investigations, the influence of matrix material, fiber volume content, and fiber distribution were shown [4].

Additionally, the optical behaviors of the polymers' thermal properties differ from those of metal structures. A very high heat conductivity of the carbon fibers compared with the un-isotropy of the material results in large heat-affected zones (HAZs) during thermal laser cutting and thus leads to unacceptable cut qualities. That is why new ideas for laser treatment are needed.

Processing with brilliant laser sources

High intensities are needed for cutting carbon fiber-reinforced polymers (CFRP) in order to sublimate or decompose the material. That is the reason why high-brilliance laser sources are recommended in combination with acceptable absorption coefficients. While the heating of metals shows homogeneous heat conductivity with constant melting temperatures, fiber-reinforced materials are characterized by an inhomogeneity in heat conductivity and sublimation temperatures for matrix and fiber material. Different processing strategies are required to minimize the interaction time between laser and material, which leads to a minimized HAZ.

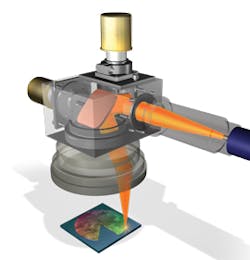

This is the reason why remote technology is used to attain acceptable results. Different designs of beam deflection optics are available in which the beam will be deflected by tiltable scanning mirrors (FIGURE 1). These systems allow the laser spot to move at up to 10 m/s within working areas of 100 cm² to 1 m². To enlarge the working area, the high dynamic axes can be coupled with conventional axes systems like robot or CNC machines.

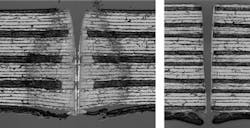

CW lasers with high laser power or pulsed laser (ns pulses or less) can be applied to improve cut quality and productivity. Based on the high scanning speeds, the ablation depth only ranges from a few micrometers to some hundred micrometers. A multicycle treatment is used to process parts of millimeter thicknesses. The laser configurations result in average cutting speeds between 0.01–3 m/min on 4 mm endless fiber-reinforced CF epoxy resin sheets with measured HAZs of only a few hundred micrometers. FIGURE 2 shows comparable cross sections accomplished with gas-assisted laser cutting (left) and high-power CW remote cutting (right).During remote processing, the waste material will not be blown out of the cutting kerf by assisted gas. All the sublimated or decomposed material has to be taken away from the ablation kerf in the direction of the laser beam. Because of that, an interaction between laser beam and evaporated material was observed where they were found to be dependent on the aspect ratio of the ablation kerf and HAZ [5].

Near-net-shape constructions

Lightweight structure engineering with textile-reinforced composites offers numerous advantages compared to conventional designs. A collaboration project at the Technische Universität Dresden is working to optimize the whole process chain from filament production to final component processing. In particular, textile near-net-shape structures and sandwich structures, handling equipment with process-adapted kinematic systems, textile-compatible joining methods and joining elements, textile-reinforced compliant structures as well as composite components with integrated sensor networks will be investigated [6].

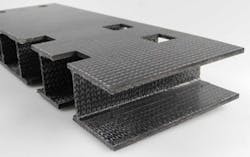

The advantage of laser cutting within this collaboration project can be shown during spacer fabric final processing [7, 8]. This structure is based on woven or knitted preforms, produced from commingled hybrid yarns. The components are glass fiber and polypropylene with a fiber volume content of 50%. Furthermore, it is characterized by multilayer constructions and cross-links in production directions. The processing of the presented lightweight spacer structure (FIGURE 3) was made possible by 2 1/2 D-beam deflection using a high power CO2 laser. In a first step, the upper layer was cyclically ablated. Subsequently a focal adjustment was performed to ablate the lower layer. Comparing those results to state-of-the-art milling or water jet cutting, the remote laser process is a force-free and low-wear treatment. Also, one-sided machining without repositioning of the work piece is a benefit. Furthermore, cutting contours can be programmed, which include thru-cuts as well as one-layer cuts with flexible geometries [9, 10].Conclusion

The use of fiber-reinforced polymers for high-volume production requires new flexible processes for final treatment. Thus, the laser could be a tool for the future. However, special strategies are needed to treat these components with different opto-thermal properties. Basic knowledge of the absorption behavior and the influence of fiber volume content and distribution is required. To minimize the heat input into the cutting kerf, the remote laser technique in combination with multicycle strategies was demonstrated. Remote processing also enables the flexible treatment of at near-net-shape parts, which was demonstrated during treatment of spacer fabric structures.

ACKNOWLEDGMENT

Part of this research was funded by the "Deutsche Forschungsgemeinschaft DFG" within the Collaborative Research Centre SFB 639 of TU Dresden, "Textile-reinforced composite components for function-integrating multi-material design in complex lightweight applications," project part: D4.

REFERENCES

1. D. Biermann, W. Hufenbach, and G. Seliger Serientaugliche Bearbeitung und Handhabung moderner faserverstärkter Hochleistungswerkstoffe – Untersuchung zum Forschungs- und Handlungsbedarf. Dresden: Progress Media, 2008. ISBN 978-3-00-026217-3

2. S. Mazumder, Composites Manufacturing, CRC Press, 2001. ISBN 0–8493–0585–3

3. R. Lässig, Serienproduktion von hochfesten Faserverbundbauteilen, Perspektiven für den deutschen Maschinen- und Anlagenbau, Studie Roland Berger, 2012

4. A. Klotzbach, A. Fürst, J. Hauptmann, and E. Beyer, "Remote processing of tailored fiber-reinforced lightweight structures," 31th ICALEO, Sept. 23-27, 2012, Anaheim (CA), US, paper 401.

5. A. Klotzbach, A. Fürst, J. Hauptmann, and E. Beyer, "Investigations on laser remote cutting of tailored fiber-reinforced structures," 2nd International Symposium on Lasers Processing for CFRP and Composites, Yokohama, Japan, Apr. 23-25, 2013.

6. TU Dresden, "Textile-reinforced composite components for function-integrating multi-material design in complex lightweight applications," Collaborative Research Centre SFB 639, Dresden, Germany, 2004–2015.

7. M. Schade, O. Diestel, Ch. Cherif, M. Krahl, W. Hufenbach, J. Franeck, and V. Ulbricht, "Entwicklung und technologische Umsetzung von komplex geformten Leichtbau-Modulträgern aus textilverstärkten Thermoplasten," Composites in Automotive & Aerospace-5, Internationaler Fachkongress für Composites, München, Oct. 14-15, 2009

8. W. Hufenbach, F. Adam, M. Krahl, K.-H. Modler, and U. Hanke, Fertigungsstrategien für die Herstellung komplexer Strukturbauteile aus Hybridgarn-Textil-Thermoplast- (HGTT-) Halbzeugen, 13. Dresdner WZM-Fachseminar, Dresden, 2008

9. M. Lütke, A. Klotzbach, A. Wetzig, and E. Beyer, "Laserschneiden von Faserverbundwerkstoffen," Laser Technik Journal (Weinheim), March 2009.

10. A. Fürst, A. Klotzbach, S. Hühne, J. Hauptmann, and E. Beyer, "Remote laser processing of composite materials with different opto-thermic properties," International WLT-Conference on Lasers in Manufacturing 2013, Munich.

Dipl.-Ing. Annett Klotzbach ([email protected]) is project engineer and coordinator and Dipl.-Ing. Andreas Fürst is project engineer, both of laser processing of fiber-reinforced materials at Fraunhofer IWS Dresden.