Laser welding in "Transmission Manufacture 2.0"

Farmington Hills, MI -- From dual-clutch transmission to the classic differential, modern transmission technology is a pivotal research sector in the automotive industry. With new materials and altered geometries, designers optimize the functionality of the different gearwheels. Furthermore, these wheels are required in ever-larger quantities, owing to the fact that the number of speed-gears in many passenger cars is on the increase. The innovations that promote the effectiveness of the production processes being applied include, for example, laser welding. The specialists at EMAG (www.emag.com) have developed integrated solutions for the application of processes with high output rates. The company’s in-depth knowledge of the production processes used for many transmission components has added to its competency in machine development.

A first glance at a typical transmission component makes it plain where the challenges lie: even a small wheel with integrated synchronous gearing represents a relatively complex design. To manufacture it efficiently and at the highest precision calls for the two different parts to be produced separately and subsequently joined in a joining+welding process. It is at this point in modern transmission manufacture that laser welding comes into its own, explains Dr. Andreas Mootz, managing director of EMAG Automation.

"The process allows you to concentrate a carefully dosed amount of the energy emitted by the laser beam on the welding point, minimizing possible warping, while still achieving high welding speeds," says Mootz. "Furthermore, our welding process uses solid-state lasers of outstanding energy efficiency. Whereas a classic carbon dioxide laser will achieve an efficiency factor of just about eight percent, the EMAG specialists can rely on an efficiency factor of approximately 20 percent with their technology. In other words, the power used to achieve the same optical performance is noticeably less, with energy costs in the production department massively reduced."

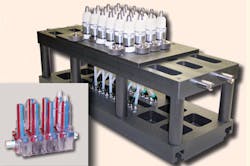

Stationary welding device

Similarly effective within the total process is the integration of different production sequences on EMAG’s ELC system. For starters, the work spindle uses the pick-up principle to load itself. The components involved are then clamped and pressed together in the joining press. The clamping technology used ensures the highly accurate positioning of the components, providing excellent conditions for the welding process. The design of the stationary optic ensures great operating safety and optimal stability of both machine and welding process.

Depending on the workpiece material, the components can be induction-preheated prior to the welding process and brushed after it -- and whatever is required, the process is completed in a single setup. The complete joining+welding process for a gearwheel takes just 12 s. This ensures that the components for a differential are thus finish-welded within no more than 40 s.

Lightweight construction

The differential housing, as an example, clearly shows the possibilities that laser welding technology opens up in the general development of vehicle production. For some time now, automotive companies have been replacing the screw-type connection between differential housing and crown gear with a welded seam. The result: material costs go down, and the weight of the assembly falls by ~1.2 kg or ~2.65 lbs.

"When looking at the advances made in lightweight construction in the automotive industry, this kind of savings means the world," explains Dr Mootz.

Seen in context, the welding specialists from EMAG Automation in Heubach, Germany, are able to look back on a truly impressive history of success. More than 50 ELC systems have been sold in the last decade, with all leading automobile manufacturers using them.

For more information, contact [email protected].

More Industrial Laser Solutions Current Issue Articles

More Industrial Laser Solutions Archives Issue Articles