Understanding processing with thulium fiber lasers

Scalability to higher powers appears likely

Tony Hoult

It is not very often that another laser wavelength becomes available at a high-enough average power and at a dollar per watt cost that makes it immediately attractive for real-world industrial applications, but that is exactly what has happened with thulium (Tm) fiber lasers. Initially developed for a surgical application at the 100 W power level, this laser has unique capabilities in many other often-unexpected fields of application, as this article will explain.

Fiber lasers so far

In common with almost all fiber lasers, high-power multikilowatt fiber lasers use ytterbium as the active medium. Their most important feature is that the beam is generated by pumping this active medium in the fiber itself, and the whole beam path is contained within one continuous fiber optic.

The industry-wide trend toward the use of fiber lasers and fiber-laser technology is well established worldwide, and the delivery of a 100 kW average power fiber laser has set a remarkable record for the industry. The move in the industry toward multikilowatt fiber lasers in the biggest industrial laser market of all, the flat-bed cutting market, confirms that there is still amplegrowth opportunities for those leading the advances in fiber-laser technology.

Nanosecond-pulsed fiber lasers have also had a huge impact on the laser marking and micromachining industries, and pico- and femtosecond lasers using active and passive fiber components are making progress at the high-precision end of the laser microprocessing market. Quasi-continuous-wave (QCW) fiber lasers with pulses in the micro- and millisecond range are also rapidly displacing the incumbent flashlamp-pumped laser technology for low-duty-cycle, high-pulse-energy welding and cutting operations. Similarly, fiber-laser components are being widely used in shorter wavelength lasers.

The role of the Lanthanides

The focus of this article is on the short-wavelength infrared (SWIR) fiber-laser wavelengths. It should be noted that high power fiber lasers emerged out of the telecom industry, and the standard wavelength for all of the early fiber-laser-erbium-doped fiber amplifier (EDFA) devices is in the 1540 nm range. Hence, leading fiber-laser manufacturers have never been solely focused on one single wavelength.

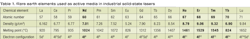

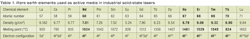

Perhaps the best place to start is with the periodic table; all of the rare earth elements that are used as active media in industrial solid state lasers are all Lanthanide family members that reside in that portion of the table that many times confused us as high school students

As we see from TABLE 1, holmium, erbium, Tm, and ytterbium (Yb) are adjacent with similar physical properties and electronic structures. This in part explains why they have all been used as dopants in active fibers. The emission wavelength, however, does not increase with ascending atomic number in the periodic table for reasons beyond the scope of this article, but the major emission wavelengths are given in TABLE 2.

Brief review of SWIR/MWIR lasers

There has been a recent increase in interest in the SWIR 1.4 to 2.1 µm spectral region in both academia and in industry. There are now several suppliers of commercial fiber lasers, solid state lasers, and direct diode laser systems available.

One early impetus behind laser developments in this wavelength regime was for surgical and dental applications because of the improved water absorption at these SWIR wavelengths, to be discussed later in the article. The first lasers to be developed were holmium YAG lasers emitting at 2.1 µm, and because of this water absorption, the beam can produce superficial tissue ablation in the human body, giving a precise incision with a small (~0.5 mm) thermal injury zone.

Fiber-laser developments, based on EDFAs for the telecom industry emitting in the 1.53–1.56 µm region, accelerated rapidly due to the telecom boom in the mid 1990s. This showed the way not only for Yb doped lasers but also for fiber lasers using Tm, the adjacent element in the periodic table. These lasers, emitting in the range of 1.9–2.1 µm, were developed due to interest in additional surgical applications such as laser lithotripsy and other urological procedures

Pulsed lasers, either Q-switched or mode-locked, are also being developed in this regime as pump sources for laser-driven particle acceleration, higher harmonic generation, low-power eye-safer LIDAR, and mid-infrared (mid-IR) frequency generation via nonlinear optical conversion by either an optical parametric oscillator (OPO) or supercontinuum generation. The high peak power of these pulsed sources allows for efficient nonlinear conversion to longer wavelengths.Radiation within the mid-IR, which is often referred to as the "molecular fingerprint" region due to its large variety of molecular absorption features, is particularly desirable for molecular sensing applications.

Lasers that directly produce radiation at longer wavelengths, in the MWIR 2–5 µm regime, are also becoming available, but it should be noted that beyond a wavelength of ~2.1 µm, the use of conventional silicate glasses becomes problematic. Fluoride, telluride, or chalcogenide glasses are required for transmissive fibers in this wavelength range.

These wavelengths are in demand for a variety of applications including spectroscopy, non-invasive medical diagnosis, laser scalpels, remote sensing, free space communications, and OPO pumping. There are also numerous defense-related applications including countermeasures, stand-off detection of explosion hazards, seekers for smart munitions, and covert communications systems that require a number of different wavelengths. For these applications, hybrid fiber/crystal lasers, some of these continuously tunable over a broad spectral range, have been developed. Diode lasers are also being developed for these applications using newer heterostructures and can produce wavelengths up to 2.3 µm at room temperatures.

Safety issues

We now arrive at a very important aspect of processing with these wavelengths; high power laser beams in this wavelength regime are sometimes incorrectly referred to as "eye-safe". It must be very strongly emphasized that there is no such thing as an eye-safe laser beam at the power and fluence levels we are discussing here. Please remember this wavelength was developed specifically because of its high absorption in water, and hence all relevant laser safety precautions must be taken. Fortunately, all high-quality laser safety eyewear has a high optical density well into this wavelength range.

Thulium fiber lasers

Both q-switched and continuous-wave Tm fiber lasers have in the last few years been developed up to higher average powers. In the case of pulsed lasers, 10 W average power is now commercially available from a limited number of suppliers. At this power, one might expect specific ablative materials processing applications such as scribing or cutting of thin films to be realized, but I am not aware of any published technical information on their processing performance or of any large scale deployment of these lasers for such applications to date. Continuous-wave Tm fiber lasers were developed up to high-average power for a group of specific surgical procedures known generically as endourology, but details of these techniques are covered in the technical medical literature. The fact that laser beams at this wavelength can be transmitted using fused silica glass optics and fibers that are readily available makes the introduction of this new technology much easier. Optical coatings specific to this wavelength are also now readily available from specialist suppliers. Reflective optics are even less of a problem in this SWIR regime because metal mirrors such as those employed for CO2 lasers may be used. For industrial materials processing, the availability of 120 W average power brings industrial laser processing well within reach, especially considering the very realistic cost model when compared to 1 µm lasers. Simplistically, at ~100 W average power in a focused laser beam, phenomena occur rapidly and on a scale that is clearly visible to the unaided (but protected) human eye.

Processing with 2 µm CW fiber lasers

Both water and hydrocarbon molecules are present in almost every physical object we encounter and are certainly present in many of the materials that are processed with lasers. Most would agree silicon is one of the most important materials in modern technology. What is really exciting is that we now have a practical, reliable, cost effective laser tool that interacts significantly differently with all of these materials. Thus, let us look more closely at the effect of 2 µm light on different material groups.

Metalloids

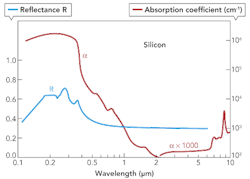

With metalloids, ample evidence in the scientific literature states that absorption is a strong function of wavelength with very important increases in attenuation length. FIGURE 1 shows that the absorption coefficient of silicon decreases gradually with increasing laser wavelength away from 1.13 µm (1.1eV) as it moves away from the band gap. As wavelength increases further toward 2 µm, the absorption drops rapidly. Laboratory trials have confirmed that it is possible to transmit 50% of the power of a 4.2 mm diameter collimated 100 W laser beam at 1940 nm through a 0.7 mm thick silicon wafer. Not unexpectedly, due to the similarity between them, we have seen similar results in germanium and would expect similar transmission in other indirect band gap materials.

A patent pending technique has been developed using this through transmission effect, and it could be responsible for a range of new thermal processes in both the MEMS and microfluidics fields. Other techniques, often referred to as "direct bonding" and "eutectic bonding" may also take advantage of this phenomenon. These techniques are of particular interest for joining completely dissimilar materials such as ceramics, glasses, semiconductors and polymers using a very thin bond layer of specific metals that have been deposited onto one of the faying surfaces. This interlayer can then be fused in a highly localized manner by the laser to bond almost any material onto the backside of a semiconductor or any transparent component.

We have also shown that power density after passing through silicon can be high enough to produce ablation on another absorptive surface that is in close proximity to the backside of the silicon. It should be noted that this applies to homogeneous materials, and inhomogeneity on the scale of even one wavelength may lead to light scattering at grain boundaries or inclusions. This is thought to be responsible for the absorption that is observed in materials such as small-grained ceramics that should be intrinsically transparent over the range of 1–2 µm.

Metals

Metals are structured materials and definite electronic band structures exist that are responsible for effective absorption of near-infrared (NIR) radiation near the surface of the metal and although some qualitative effects suggest reflectivity from metal surfaces might be increased marginally at 2 µm when compared to NIR 1 µm radiation, we are not aware of any evidence of a strong effect.

Non-metals

This super-group of materials is often split into organic and inorganic compounds. As absorption begins at the molecular and bond energy level and because of the ubiquity of both hydrocarbon and water molecules, the discussion will be centered around hydrocarbons, the C–H bond, and the –OH bond and H2O molecule.

Organic thermoplastic polymers

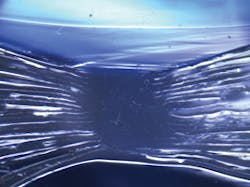

This group is the most noteworthy example of a material type based on hydrocarbon bonds that are widely used in industry. The structure of these materials is very different from metals; segments of the long chain macromolecules that make up commercial polymers can oscillate by elongating, bending, or rotating when resonant frequencies of the molecular bonds are stimulated; this is thought to be the case with Tm laser wavelengths. These wavelengths in the 2 µm spectral range are close enough to the first overtone of the fundamental C–H bond stretching absorption at 1.7 µm to create "vibronic" excitation. Originating from the combination of the terms " vibrational" and "electronic," this term denotes that in a molecule, vibrational and electronic interactions are interrelated and influence each other, and chemical alteration is less likely to occur than at shorter wavelengths. The practical effect of this, as we have seen in our lab every time we use the Tm fiber laser, is that almost all unfilled polymers absorb significantly more than at the 1 µm regime. Using the spatial and temporal control of a laser beam, this Beers Law absorption through the volume of the material, shown in FIGURE 2, leads to highly controllable melting of almost all optically clear thermoplastic polymers.

This new technique removes the main limitations of the through transmission laser welding (TTLW) technique and also eliminates the need for specific IR absorbers that are currently required when using the TTLW technique for joining clear polymers.

Semi-crystalline and amorphous polymers

This is a further important subdivision of polymer types that affects laser processing. Laser melting of commercial polymers is very different from melting metals due to the huge variety of different polymer types and blend compositions and the major differences in absorption between them. However, if this discussion is limited to optically clear or translucent polymers, this problem becomes easier to understand; obviously, there are far fewer constituents added to these polymers that might affect absorption. The major difference that then becomes apparent is the difference between amorphous and semi-crystalline polymers. The scattering effects due to material inhomogeneity mentioned previously in the context of ceramics is also applicable here; semi-crystalline polymers such as polypropylene and polyethylene scatter more and hence may require rather slower multipass heating to avoid degradation unless materials are <0.5 mm in thickness. This may also limit the maximum thickness of semi-crystalline polymer components that may be joined by this technique. Amorphous polymers such as acrylic (PMMA) and polycarbonate (PC) may usually be melted and bonded at a higher heating rate using a single pass and maximum thickness is less of an issue; however, the applications for this technology appear to be for joining thinner walled smaller high-precision polymer components.

Collaborative work is ongoing with Eastman Chemicals to compare laser bond strength with the strength of ultrasonic welds. The material under investigation is Tritan co-polyester (COPET), which is a very successful BPA-free polycarbonate substitute, widely used for a range of consumer and medical device products. Early results have shown equivalent, and in some cases, superior bond strength to that achieved using ultrasonic joining techniques.

The mechanical strength of polymers will rarely match that of metals so the effective joint areas need to be large if the joint strength is to approach the strength of the parent material. Combining this with the low thermal conductivity and low thermal diffusivity of polymers means that close to 100 W average power is often required for joining thicker materials (~3 mm) with a typical weld width of 2–3 mm at realistic speeds.

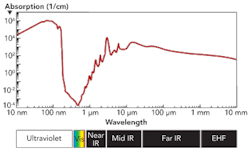

Absorption in water

The strong absorption band for liquid water occurs at around 1950 nm due to the fundamental O-H stretching vibrations. This is close enough to the wavelength of a standard Tm fiber laser for significantly improved absorption to occur. The prevalence of water in many organic and inorganic compounds means that a huge variety of materials have improved absorption in the 2 µm spectral regime; see FIGURE 3. Obviously, the improvement in absorption is very difficult to quantify because of the many different forms that this –OH bond might take. Clearly the effect could be the basis of many processes in which a controlled localized dehydration technique is required.

Relevance of fiber lasers

One of the many advantages of the fiber laser is brightness (or focusability), which is directly responsible for the ability to produce small tightly focused laser beams for ablative laser processing. Although a high-brightness Gaussian beam might be seen as detrimental for the low-power-density thermal techniques introduced here where very small spot sizes are not usually required, 2 µm lasers with larger diameter multimode fibers are also now available as they are for high-power multikilowatt near-IR fiber lasers. These give flat-top or pseudo flat-top beams and this in turn means that if large thermally treated areas are required, a collimated unfocused parallel beam may be employed, greatly reducing system complexity and cost.

Summary

The laser industry would now agree that the scalability of the Ytterbium fiber laser has already been demonstrated and Tm fiber lasers are based on the same concepts, so scalability to higher powers appears very likely. If we look back over the 50 years of the laser industry, we see that in common with other laser types, and in particular in common with continuous-wave Ytterbium fiber lasers, when around 100 W average power is available in a compact reliable industrial package, lasers suddenly became relevant for implementation in a range of macro industrial processes, and important commercial applications started to emerge. Thulium fiber lasers are now at this same point.

Tony Hoult([email protected]) is with IPG Photonics Silicon Valley Technology Center, Santa Clara, CA, www.IPGPhotonics.com. He is also a frequent contributor and an Editorial Advisor to Industrial Laser Solutions.

More Industrial Laser Solutions Current Issue Articles

More Industrial Laser Solutions Archives Issue Articles