Lasers and design: A perfect partnership

Cutting technologies gets creative

David A. Belforte

While designers, artists, and other creative people have been exploring the effects of laser cutting and engraving for aesthetic purposes for some time, Cutting Technologies prides itself on being an expert in this particular use of laser technology. Set up in 2003 and based in Barnsley, South Yorkshire, England, the company now employs 32 staff at its growing laser cutting and engraving company. They have worked hard to maintain their traditional steel and engineering customer base, which continues to form the largest percentage of their work, while diversifying into creative and design-led sectors.

Operating out of a 18,000-sq.-ft. warehouse, the company now has six lasers, including a low-power small bed 20 W Nd:YAG Trotec 700 × 400 mm used for engraving metal parts; an Epilog 60 W CO2 900 × 600 mm used predominantly for engraving plastic and wood; and a low-power large bed Eurolaser 200 W 3 × 2M capable of cutting and engraving wood and plastic on a large scale. Cutting Technologies also has Bystronic lasers, which are 4.4 kW, 3 × 1.5 M machines with all the bells and whistles to cut incredible detail, mainly in metals. Cutting Technologies (www.cut-tec.co.uk) has invested around £2 million in technology to ensure it offers the best range of laser cutting and laser engraving services in the UK -- and the company doesn’t think there is anyone else that can cut a 3000 × 1500 mm sheet of stainless steel and then engrave across the whole surface.

Getting creative

Lasers are very flexible manufacturing machines. In some respects, they are the Leatherman multitool of production. Lasers are used in everything from changing the surface of aircraft wings (to improve aerodynamics) to producing major art installations throughout the world. They can cut, weld, anneal, etch, engrave, harden, and even vaporize materials. This flexibility led the company to assess what it was doing with its machines, and what it could potentially do with them in the future. There were two schools of thought -- does Cutting Technologies get technical (the aircraft wing) or does it get more involved with the creative industries?

"While we originally began as a very traditional laser cutting firm, with our work heavily focused on the engineering market, over the last few years, we began to see more and more creative work coming our way," said Jane Robinson, co-founder and director at Cutting Technologies. "The complexities of the work involved and the occasional difficulties associated with interpreting some designers’ more obscure ideas understandably cause some laser firms to shy away from those types of projects. We, however, grew to love the challenge and now we actively market to the design and creative industries."

Earlier this year, the company had a great opportunity to work with the team at Valchromat. Developed by Valbopan SA, Nazare, Portugal (www.valchromat.pt) in 1998, Valchromat is a high-quality, colored engineered wood product that is used by architects and designers across the world. Unlike MDF, Valchromat is a wood fiber panel where all the fibers are colored individually, impregnated with organic dyes and chemically bonded together by a special resin. It’s moisture resistant, has high mechanical strength, and combines the natural features of wood with vibrant colors, making it perfect for creative work.

Cutting Technologies decided to experiment and discover the potential this material had. After a few days spent testing different effects, the company was delighted with the results, and the team at Valchromat were thrilled to see their product being used in new and innovative ways.

Valchromat has proven to be a good material for both laser cutting and engraving, and Cutting Technologies has created some stunning pieces of work, from laser-cut decorative panels to entire photographs delicately engraved onto sheets of Valchromat (see photos in FIGURE 1) The thickest Valchromat panel is 30 mm, but laser cutting has allowed the company to create intricate, detailed designs that still have considerable strength. Lots of the work done with Valchromat to date has involved routing, but the sharpness of laser cutting enables designers to think about different patterns and shapes.

The natural features of Valchromat, being a wood product, make it well-suited for laser engraving and add a real depth to the images and designs the company engraves. Cutting Technologies has been able to produce some truly incredible effects by simply laser engraving a photographic image onto Valchromat.

A strategic partnership

Now Cutting Technologies has a strategic partnership with Valchromat, and both companies are working hard to encourage the creative world to embrace both the material and Cutting Technologies’ specialist techniques. One of their major successes in introducing laser cut and engraved Valchromat was the use of the material in "Enlightened", an exhibition they hosted earlier this year.

"Enlightened" was all about showcasing the creative potential of lasers, and the company invited a series of designers from throughout the UK to come up with designs that incorporated laser cutting and/or engraving. Valchromat as well as steel, acrylic, mirrors. and wood played a key role, with a number of exhibits produced in the material.

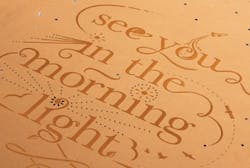

Anna Mullin, who works under the name Sneaky Raccoon, is a London-based designer who decided to use Valchromat for her typographic piece entitled "See you in the morning light" (FIGURE 2). The exhibit, which comprised three identical pieces in different complementary tones, used both gradient engraving and cutting. Backlit to enhance the cut out detail, "See you in the morning light" was a good example of how Valchromat can be cleverly combined with advanced laser cutting and engraving to create clean, digital-based art with a soft, natural effect.

"While laser cutting parts for engineers and fabricators and practical laser engraving for products like control panels and identification plates will always play a crucial part in our activity, ventures like the partnership with Valchromat help us to ensure the world sees the full creative potential of lasers," concludes Robinson. "We’ll keep showcasing the possibilities of laser technology in design wherever we see an opportunity."

More Industrial Laser Solutions Current Issue Articles

More Industrial Laser Solutions Archives Issue Articles