Femtosecond laser glass cutting yields high bending strength, cut quality

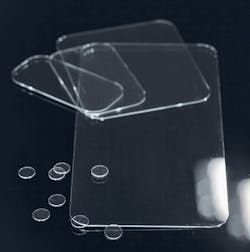

SANTA CLARA, CA – Spectra-Physics, a Newport Company, has introduced its ClearShape femtosecond laser process for high-quality, fast cutting of chemically strengthened glass, unstrengthened glass, and sapphire (FIGURE). At speeds over 1000mm/s, the process results in no chipping, Ra <0.1µm edge roughness, and as-cut bending strength of >650MPa for chemically strengthened glass. Using the company's Spirit industrial femtosecond lasers, the new process has utility in 24/7 manufacturing of displays and windows for mobile devices, wearables, and other demanding applications.

The company has also added the Spirit 1040-16 industrial femtosecond laser to its Spirit line. The new laser delivers >16W average output power with ultrashort <400fs pulse width, 40µJ pulse energy, and repetition rate up to 1MHz. Uses include fast, cold micromachining of semiconductors, flat panel displays, and other microelectronics manufacturing applications.

For more information, please visit www.spectra-physics.com/spirit.