Ultrafast lasers for consumer electronics

Advances in beam delivery enable high-precision manufacturing

ERIC MOTTAY

Today, ultrafast lasers (ultrafast-pulsed lasers with pulse durations in the femtosecond and picosecond range) are an important part of many industrial processes. The ability of these lasers for high-quality, virtually athermal material processing, coupled with advances in laser technology, process development, beam handling, and delivery, have opened the door for numerous advanced scientific and industrial applications. However, to achieve economic break-even points, several criteria must be simultaneously fulfilled. First, the technical feasibility of the industrial process has to be demonstrated. Because of the unique nature of ultrafast laser-matter interaction, this usually requires a sophisticated scientific understanding of the process. Second, the productivity of the industrial process must guarantee a sufficient return on investment for the end user. This has led to an important effort in laser development towards high-average-power ultrafast lasers, which in turn requires advances in beam handling and delivery to take full advantage of the potential processing speed.

Nowhere else than in consumer electronics applications are these trends more in evidence. Cell phones, microprocessors, display panels, and memory chips are extremely sophisticated components, comprising a large number of different materials, multiple layers of extremely low thicknesses, and very small features. They require advanced and high-precision manufacturing processes, as well as the capability to be produced economically in large quantities. The following examples will outline the need for simultaneous development of process understanding, laser technology, and new beam delivery technique to meet present and future challenges.

Manufacturing flat-panel displays for cell phones, tablets, or TVs is one of the most complex technological endeavors today—on par with the Apollo program development in the 1960s or arguably even more difficult. The different production steps involve a number of different materials, with micrometer lateral resolution and layers a few 10s of nanometers thick. Given the difficulty of the entire process, it is no surprise that the industrial yield (the percentage of units that pass the stringent quality control) is both a closely guarded secret and a major challenge. A key limitation is the presence on a panel of a few "dead" pixels, which will prevent the commercialization of the screen. For the past several years, different repair processes—usually involving multi-wavelength nanosecond lasers—have been developed. For instance, a bright pixel might be destroyed, either by laser carbonization or by cutting the electrode of the thin-film transistor controlling the pixel (FIGURE 1).

Today, current techniques are reaching their limits. Because of the improvement in the resolution of high-definition screens, the pixel size is becoming smaller and thermal effects associated with nanosecond laser processing are limiting the quality of the repair. Moreover, new display technologies, such as organic LEDs (OLEDs) and active-matrix OLEDs (AMOLEDs), make extensive use of organic and polymer materials, which are highly sensitive to heating and incompatible with thermal processing. Because of their very short pulse duration, ultrafast lasers allow for virtually athermal micromachining without any heat generation. Their increasing use in the advanced display repair process led to the development of a new generation of compact, high-speed, multi-wavelength ultrafast lasers.

Several industrial processes have been developed to take advantage of the high precision of ultrafast laser processing. This includes selective layer ablation, where ablation rates as precise as 30nm per pulse are routinely achieved, and high-precision thin-film transistor electrode cutting, which has a cutting width smaller than 2μm. These processes require the development of advanced and flexible beam shaping techniques, allowing the delivery of uniform, flat-top beams with variable shape to the sample and sizes as low as 2 × 2μm.

In another example, semiconductor circuits are becoming increasingly sophisticated. They integrate more functions, with smaller feature sizes. To this end, wafers are now comprised of many layers of multiple materials, such as low-k materials for faster operation. An important process in semiconductor manufacturing is the wafer dicing—or singulation-step, where a wafer is cut into individual dies (FIGURE 2). Traditionally done with diamond saws, current techniques are now reaching their limitation. Due to low-k materials' brittleness, lower thickness, and high number of layers, adverse effects such as cracks and delamination are increasingly liable to occur.

Although there is a strong development drive using ultraviolet (UV) nanosecond lasers, the thermal effects associated with nanosecond laser processing represent a strong limitation in the quality of the results. On the other hand, ultrafast lasers have demonstrated their capability to process silicon and multiple materials with a high quality. Until recently, a main limitation was the limited average power available from ultrafast lasers, which severely limited the overall throughput. The recent development of industry-ready, high-reliability femtosecond lasers in the 50–100W range allows reaching throughput compatible with industry requirements.

Ultrafast lasers are an essential part of many advanced micromachining processes, and they also play a significant role in quality control and metrology. Rudolph Technologies (Flanders, NJ; www.rudolphtech.com) recently introduced a new industrial tool for the measurement of opaque thin-film thickness in the semiconductor industry. The system is based on acoustic wave measurement and uses a very short, laser-generated ultrasound pulse. The timing of the reflections of this ultrasound pulse on the various layer interfaces is measured using a pump-probe technique with high accuracy.

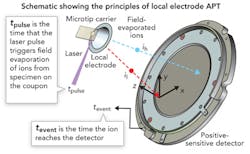

In another example, CAMECA (Gennevilliers, France; www.cameca.com) is able to perform 3D imaging and analytical characterization of semiconductor and metal samples, with atom-scale resolution. This incredible measurement process is based on a technique called atom-probe tomography, which involves irradiating a nanometer-radius tip of a sample with an ultrafast laser (FIGURE 3). If the power of the laser is carefully controlled, instead of laser ablation, a gentle atom-by-atom evaporation takes place. Each atom is then sent onto a position-sensitive detector, which determines the location on the tip from which it comes. In addition, a time-of-flight mass spectrometer measures the atomic weight and, therefore, the tip composition. Then, 3D reconstruction is performed layer by layer. This method is used in the semiconductor industry to monitor the composition and impurities of the semiconductor material, as well as in metallurgy to control, at a very fine scale, the quality of metallurgical alloys.

Manufacturing and quality control benefit from the increasing availability of high-power, high-reliability laser systems. More specifically, ultrafast lasers with average power in the range of 50 to 200W increase throughput and productivity, and, in a virtuous circle, allow the development of new applications. And yet, beam handling and delivery of such high-power lasers is not straightforward. Processing speeds of up to 100 m/s are required to reach economic break-even while maintaining micrometer-scale positioning accuracy. And the current generation of galvanometric mirror-based scanners is reaching its limit, calling for new approaches.

ESI (Portland, OR; www.esi.com) has introduced a hybrid processing system that combines galvanometer mirrors and acousto-optic technology. When operating at a high processing speed, the inertia of the scanner mirrors means that they will lag somewhat when performing, for instance, a sharp turn, so the processed structure will not have the desired shape. Acousto-optic modulators, however, exhibit extremely high reactivity, but on a very small field. The combination of mirror movement and acousto-optic deflection, precisely synchronized, overcomes this limitation. Such a technique is especially useful in the manufacturing of interconnected digital circuit patterns, which are becoming more tightly integrated and require increased wiring density.

Researchers at DISCO (Tokyo, Japan; www.disco.co.jp) have combined the two approaches by simultaneously performing micromachining and process control with the same laser. The application in this case is blind via-hole drilling of a two-layer substrate with an ultrafast laser. The upper layer is a transparent material with a thickness of 80μm and the lower layer is a 20μm-thick metal film. To precisely control the number of laser pulses required to achieve ablation of the transparent substrate only, the plasma emission is monitored with an optical spectrum analyzer using a technique known as laser-induced breakdown spectroscopy (LIBS). Since the plasma emission has a unique emission spectrum depending on the atomic species being ablated, it is possible to clearly and accurately identify the instant when the transparent layer is fully ablated.

In another approach, polygon scanners can provide scanning speeds greater than 100 m/s. Instead of using low-inertia galvanometer mirrors to deflect the beam in the x and y directions, a single, multifaceted polygonal mirror rotates at a high speed. If the pulse laser is precisely synchronized with the polygonal mirror rotation, only a single spot per facet may impact the sample to be processed. In this case, the micromachining process is closer to a digital process, where the laser has to be switched on and off to produce the desired pattern. To be successful, though, this approach requires very precise synchronization between the laser and the scanner, high manufacturing accuracy of the polygonal mirror, as well as a carefully designed process. Prof. Beat Neuenschwander (Bern University of Applied Sciences, Switzerland; www.bfh.ch), in collaboration with Amplitude Systèmes and NextScan (Evergem, Belgium; www.nextscantechnology.com), has demonstrated high-speed surface texturing with a 500kHz ultrafast laser and micrometer-scale repositioning accuracy.

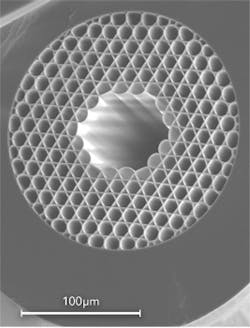

Still, more innovative beam delivery approaches are on the way. Industrial ultrafast lasers, until recently, were not able to benefit from fiber-optic delivery systems, which have transformed laser manufacturing. The confinement of the beam in a small fiber core, combined with the very high peak intensity associated with ultrafast pulses, gave rise to severe nonlinear effects and ultimately fiber degradation. To mitigate this limitation, microstructured fibers with hollow cores have been developed, but their core diameter is limited to a few microns-too small for practical use. The development of hollow-core, large-mode-area Kagome microstructured fibers paves the way for fiber delivery of high-energy, high-power femtosecond laser beams. The special, hypocycloidal shape of the hollow fiber core confines the laser mode, prevents it from interacting with the fiber microstructure, and provides a combination of low nonlinearity, large mode area, and flexible dispersion control. In collaboration with the company Glo Photonics (Limoges, France; www.glophotonics.fr), Amplitude Systèmes has demonstrated the delivery of millijoule-class pulses over a distance of several meters, while maintaining a sub-500fs pulse duration. In another set of experiments, performed in a collaboration with the company Photonics Tools (Berlin, Germany; www.photonic-tools.de), average power of 100W has been transmitted and pulse compression to sub-100fs pulses has also been demonstrated. Other teams and laser manufacturers are quickly refining and developing flexible delivery systems using Kagome fibers (FIGURE 4), and we can expect a profound transformation of ultrafast laser processing systems in the years to come.

Enabled by advances in the physics of short-pulse laser-matter interaction, as well as technological developments in beam handling and delivery systems, ultrafast lasers have made their way into the heart of our daily lives. Deeply embedded into the most advanced industrial manufacturing processes, they are changing the way we see, the way we communicate, and the way we work, and are a key of future generations of consumer electronic devices of increased complexity.

ERIC MOTTAY ([email protected]) is the president and CEO of Amplitude Systemes, Pessac, France (www.amplitude-systemes.com).