Capturing magical moments

Minden, Germany - It’s not surprising that a company that claims its system setup is “child’s play” would demonstrate the system on a cruise packed with children. Indeed, the emergence of compact, reasonably priced systems is expanding the applications of marking and engraving in many different industry sections, including gift items and memorabilia.

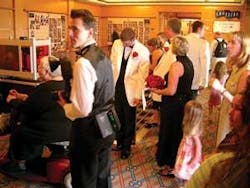

Earlier this year, Cerion GmbH (www.cerion.biz) literally rolled onto a popular cruise ship with its X2 compact internal glass engraving system and set up shop for a week-long, Eastern Caribbean cruise. While onboard, the company offered passengers portrait photo engraving in glass. Internal engraving refers to the two- and three-dimensional, sub-surface marking of transparent materials. The glass surface remains completely unaffected by this process.

During the seven-day cruise, a two-man team operated the system between seven and eight hours per day without problem. “Passengers responded very positively,” says Volker Wienkamp, company spokesman. In fact, he estimates that they serviced 20 customers minimum every day. Passengers could choose between a 50 x 50 x 80 mm 3D cube and a 130 x 170 mm 2D glass plate. Processing time for each customer was between 10 and 15 minutes.

The system was specially designed for mobile use and in laser shops. It uses a Nd:YAG laser (532 nm) to produce up to 1400 points per second with 2W of power. The user controls the system from a Notebook PC (supplied with the system) via a connecting USB cable. The required 3D camera system, also controlled from the Notebook PC, enables users to obtain photographs that are down to a fine level of detail and that have a strong contrast in glass.

The unit is sealed against laser radiation thanks to generously sized filter-glass doors. This way, the sub-surface engraving process, which itself is quite entertaining, can be demonstrated without risk and customers can see how their 3D portrait is created inside the glass.