New horizons in laser welding

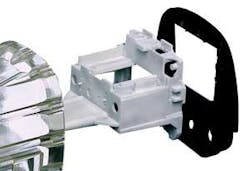

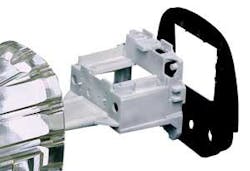

Gaggenau, Germany - Three years ago Precitec KG (www.precitec.com) introduced a high-power, 6kW solid-state laser welding head. To prove endurance the company needed to use the power from two lamp-pumped rod type lasers delivered through twin fiber into the welding head.

Today the company has proven the optimized design of this welding head by using it with a 10kW fiber laser from IPG (www.ipgphotonics.com). This high-power capability is a result of the optical design that uses high-purity quartz substrates and built-in water-cooling circuits to eliminate the small percentage of absorbed laser power (less than five percent).

The fiber laser, which was first tested at BIAS Bremen (www.biass.de), starts welding with a loud bang if the laser is started above the specimen without a power ramp. The first tests with 200mm focal length easily destroyed a cover glass slide because of the start explosion without power ramping and a very large plasma plume beneath the Cross Jet. In tests at SLV-Rostock (www.slv-rostock.de) a 250mm focal length produced higher lifetime of the optical components.

Currently the optical setup is a collimator with 125mm and a focusing lens with 250mm focal length. Using the 200-micron core diameter IPG fiber produces a spot of approximately 400-micron diameter, which is sufficient for high-power welding.

Tests were performed with steel and aluminum alloys as autogenously or gas metal arc assisted welds. For autogenous welding the speed is between 2m/min for 12mm thickness and 15m/min welding speed at 4mm thickness. Aluminum shows a slightly higher welding speed at the same penetration as steel material. In aluminum welding there is a blue plasma plume between the work piece and nozzle.

The next challenge is a 15kW welding head, which was to be supplied in February 2005. - DAB