Processing packaging material

Jena, Germany - Jenoptik Automatisierungstechnik GmbH has 14 years’ experience in the processing of large webs and composite materials, specializing in cardboard, paperboard-plastic, paperboard-aluminum-plastic composites, and single or multilayer plastic film.

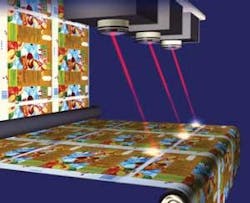

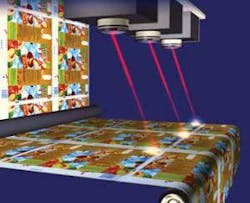

Scanner systems move the laser beam across the material, so almost any shape or structure can be generated at maximum speed. These laser systems are integrated in production lines in which material runs at speeds of up to approximately 400 m/min web to web.

The main uses of these systems are in the packaging materials industry, notably the production of cartons for liquids and for flexible packaging made of plastic film. They generate shapes and structures by the following methods: cutting, perforating, preweakening material, lettering, and combinations of any of these methods.

The best-known example is opening aids in beverage cartons, where the laser generates line or hole structures by removal of defined layers of material without destruction of lower layers. This reduces the thickness of the packing material and assists the opening behavior of the box by preweakening. Thus, a carton, for example a juice carton, can be opened manually without loss of tightness or sterility. Processing speeds of the order of 350 m/min can be obtained.

In addition to the high quality of the processing results and the very high processing speed, the integration of the laser equipment in the production line has other advantages. Due to the fact that complex and difficult-to-set mechanical semislicing tools are not needed, the geometrical shape and the processing parameters can be changed as needed and parameter records saved. Thus, the changeover from one product to another can be completed within minimum time.

For integration of the laser equipment in the production line, laser scanning systems are installed above the material. Each scanning system can also work independently. This way, the lack of material uniformity and web thickness differences can be compensated in several-up production. Usually, three to six laser scanning systems are arranged in parallel.

Interested companies can contact Jenoptik at www.automation-jenoptik.de.