Rapid manufacturing in interior design

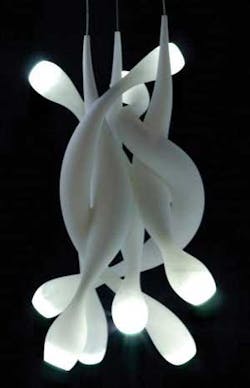

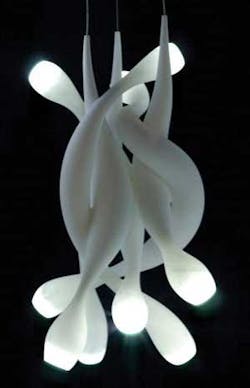

Krailling, Germany - Innovative domestic lighting has entered commercial production at Materialise (Leuven, Belgium) using plastic laser sintering machines from EOS Electro Optical Systems. As detailed in ILS in November, laser sintering has matured to a technology for batch-sized, optimized production, including end products and spare parts.

Based on CAD models, the lights can be customized to suit a customer’s individual requirements, made possible by simply mutating the electronic data on-screen and then downloading to the laser sintering machines. The lights are created by British designer, Lionel Theodore Dean, proprietor of FutureFactories.

Says Dean, “This is the first step towards widespread customization of products to suit individual preferences. It revolutionizes the way that interior decorators and designers assemble their collections and create limited editions to satisfy their clients’ wishes. The ultimate goal is to unleash a new era of mass-customized designs in which we are able to meet and exceed the customer’s wildest dreams.”

He is currently extending his use of plastic laser sintering to furniture projects and comments that the level of complexity that he is able to design into all his products could not be made a physical reality using conventional manufacturing techniques such as molding and machining.

From a number of different rapid prototyping and manufacturing techniques available, Dean has identified laser sintering as the best method for producing his products. Several years ago he started using a relatively crude 3D paper system and moved on to thermo-jet printing to produce patterns for investment casting of complex metal parts. With lighting, however, translucency of the material is paramount and laser sintered plastic has proved to be ideal.

Dean continues, “Materialise also has stereolithography machines, but my lights have proved to be more functional when produced using the laser sintering process, which has greater flexibility as support structures are not needed.

“I can achieve half-millimeter wall thicknesses that are robust enough for practical use. So I do not have to beef up sections, which would compromise on light transfer through my products, and clip mountings are sufficiently strong to hold sections together without breaking.

“EOS in the U.K. was a big help in researching the best material to use, which was identified as 50-micron polyamide (nylon) powder. It has the extra advantage of high resistance to heat as well as to mechanical stress.”

FutureFactories’ lighting products already in commercial production in Leuven are ‘creepers’ and ‘RGB’ (see www.futurefactories.com). The more recent ‘Tuber9’ design (see photo) will follow. Meanwhile, it has received the considerable accolade of being accepted for the permanent design collection in The Museum of Modern Art (MoMA) in New York. For further information, e-mail [email protected] or visit www.eos.info.