A new method of laser surface modification

Complex surface features in metallic materials made with a low-Power beam process

Paul Hilton and Jonathan Blackburn

This article relates to a new power beam process that enables controlled surface features to be produced on a range of substrates such as metals, polymers, and ceramics. In application, a rapidly scanned power beam melts material. The molten material subsequently moves, in part, due to the surface tension generated by a temperature gradient created across its surface. Note that no material, for example wire or powder, is added; the process is entirely autogenous in nature. How the material moves, and ultimately the shape of the features produced, can be determined by precisely controlling the beam path and its speed over the surface. The process can manufacture features that may be identical or different. In particular, the scale of surface features available offers performance benefits for a number of applications, including orthopedic implants, composite to metal joining, heat exchangers and aiding in the application of ultra-thick coatings.

A key characteristic of the process is that the beam makes multiple returns to the same point and multiple swipes to sequentially build individual surface features. These characteristics differentiate it from conventional surface texturing processes. Both electron beam and laser beams can be used to produce features by this method, which has been trademark-registered as Surfi-Sculpt. This article will discuss the laser variant, in which optical power is used to melt and displace material, thereby creating the surface feature.

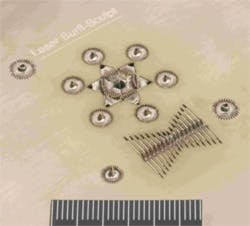

To perform this work, two recent developments in laser materials processing are utilized. High-brightness lasers have the advantage that their beams can be focused to small spots of high power density, while still using a beam focusing lens of long focal length. This large distance between the focusing lens and the focused spot is needed because the rapid manipulation of the laser beam required for the Surfi-Sculpt process is achieved by orthogonally mounted and galvanometer driven beam scanning mirrors. Recent developments in this latter field have produced a new generation of laser beam scanning systems capable of operating with kilowatts of laser beam power. In the work described here, both disc and fiber lasers have been used at relatively modest laser powers of between 200–1000 W, in conjunction with two different laser beam scanning systems. FIGURE 1 provides an initial indication of the type of features that can be produced using this technique.

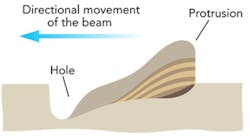

FIGURE 2 shows a simple representation of how a linear feature is developed using this process and shows successive movement of a laser beam focused on the surface of the material. Note the direction of the beam’s motion. Material melted by the beam on its first pass flows back along the beam path before it solidifies, producing a slight protrusion at the initial point of contact of the beam and a slight depression at the end of the beam “swipe”. Provided the heat input to the process is correctly managed, then successive swipes of the beam magnify this effect to the point where protrusions several mm in height can be formed.

FIGURE 3 shows an SEM image and photo of such a linear sculpted feature. Each feature was built up from 400 repetitions, one on top of the other, over a 4 mm swipe length. The laser beam scanning speed was 600 mm/sec. The SEM images, in particular, show clear evidence of cyclic movement and solidification of material. The features shown were made using a 200 W single mode fiber laser and a conventional laser marking scanner and software.

More complex shapes

Introducing more complexity to the scan pattern enables more complex shapes to be formed. In the initial series of experiments, patterns were limited by the sophistication of the scanning software packages, which were not written with this process in mind. However, several interesting possibilities were still possible, such as the cones shown in FIGURE 1. These were made by successively scanning the beam away from a central position, while rotating the swipe angle during the beam-off time. The fine features shown in FIGURES 1 and 3 were produced with a laser spot size estimated to be about 40 µm in diameter using the single-mode fiber laser. It was also possible to produce similar effects using higher-power multi-mode fiber and disc lasers. All the features shown in FIGURES 1 and 3 were made on titanium plate using argon shielding gas. The process works in a similar way on Inconel, C-Mn steel, 304 stainless steel and even 7000 series aluminum. However, for the same processing conditions and programmed scan path, each feature is slightly different. These differences are believed to be due to the physical properties of the different materials and how these relate to the physics of the process. Clearly, viscosity of the molten material, its surface tension, thermal conductivity, and reactivity to atmospheric oxygen will all play a part.

FIGURE 4 shows a series of protrusions produced on a 7000 series aluminum plate made in air. In this case, the laser power was 1 kW from a disc laser and the sweep speed of the beam was 26 mm/sec. The height of each feature is about 2.5 mm. For comparison, FIGURE 5 shows features produced using a similar scan pattern on titanium plate (using an argon shield). This time, a laser power of 750 W was used, and 16 legs form the basis of the feature. The domes produced were again about 2.5 mm in height.

FIGURE 5. Features in titanium.

FIGURE 6 shows the construction of a “wall” feature in Inconel alloy using the 200 W single-mode fiber laser. In this case, the scan patterns all terminated at the same point. The feature height is about 2 mm. This type of scan pattern and others have been combined to produce the array of features shown in FIGURE 7.

The experimental work has shown that the process works best if the intervals between particular swipes in the feature are arranged so that the temperature distribution in the work piece is carefully managed. Without attention to this point, treatments may not produce high-aspect-ratio builds of any kind, or may give features that self-limit in height or even simply melt. Software packages available with current laser scanning systems cannot accommodate this capability easily, for the simple reason that they were never designed to do so. It is thus felt that to fully optimize the capability of this new process, some alterations to the existing software controlling the scanning laser beams will have to be made, if the process is to be implemented simply in an industrial context.

The work described here indicates that a wide variety of surface features can be reliably produced in a range of metallic materials using a relatively low-power laser beam. Furthermore, the cost of such a system, including a small fiber laser and a conventional laser marking scanner, is reasonably cheap.

Emerging applications

There are a number of emerging applications for fine-feature surface manufacture — for example, biomedical devices and implants, where the integration of implants into the body is highly dependent on the surface. Specific small-scale features are required to promote bone growth, for example, and these features are presently difficult and expensive to produce by other methods.

The process described here offers the benefits of being relatively fast, allowing close control of feature shape and ensuring surface features are firmly bonded so that they do not detach from the implant. In addition, from electronic devices to aircraft engines, currently available heat transfer surfaces and structures limit product performance. New and bespoke surface features are needed to provide additional freedom of design that will address the need to reduce size and weight and improve efficiency.

Thus, there is a demand for sophisticated, cost-effective, volume surface manipulation of heat-exchanging surfaces (e.g., fins) to increase the surface area for heat transfer, and introduce vortices into the airflow over the surface, both of which enhance micro- thermal management. More effective heat transfer would allow components to be reduced in size for a given thermal performance requirement, reducing material consumption.

In the area of lubricating surfaces and surface tribology, component design dictates the wear rate and time between servicing of many products (e.g., bearings, mechanical seals, and vehicle engine parts). Designers require intelligently tailored bearing surfaces, leading to reduced friction and wear, oil and fuel consumption, and emissions. This is particularly relevant to the automotive and aircraft industries’ drive to meet proposed European mandates, e.g. for NOx, CO2 and particulate emissions. Bearing performance is also relevant for many other sectors, including process plant, aerospace, and domestic products. Designed surface textures of micro-features are needed to serve as micro-hydrodynamic bearings in cases of full or mixed lubrication, micro-reservoirs for retention of lubricants, or micro-traps for wear debris in lubricated or dry sliding.

Finally, the application and performance of thermal barrier coatings for high-temperature devices, deposited by current process technology (e.g., plasma spray or physical vapor deposition) is limited by the relatively low strength of the coating to substrate bond — the impact of thermal expansion mismatch at elevated temperature often causes premature component failure. Enhanced surface structures can be used to both grade coatings and provide enhanced mechanical locking to the surface, which would be beneficial in emerging power generation technologies such as biomass combustion waste incineration, where combustion products are particularly aggressive to structural materials.

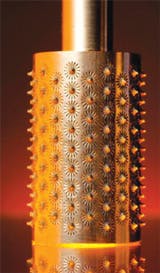

The final image (FIGURE 8) shows a series of laser induced features on the side of a stainless steel cylinder having a diameter of approximately 30 mm. The cylinder can be rotated across a surface requiring perforation. ✺

Paul Hilton and Jonathan Blackburn are with TWI Ltd Great Abington, Cambridge, UK. For further information, contact [email protected] or [email protected].

More Industrial Laser Solutions Current Issue Articles

More Industrial Laser Solutions Archives Issue Articles