Selective laser etching of sapphire glasses

Jens Gottmann, Martin Hermans, Maren Hörstmann-Jungemann, and Dagmar Schaefer

Process produces microchannels and shaped holes

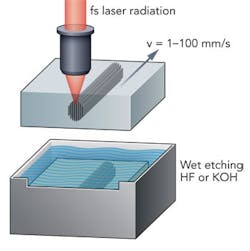

With the new In-volume Selective Laser Etching (ISLE) technique, the Fraunhofer Institute for Laser Technology (ILT), in cooperation with the Chair for Laser Technology (LLT) at RWTH Aachen University, provide the first process for producing microchannels and shaped holes and cuts in transparent parts made of fused silica, borosilicate glasses, sapphire, and ruby. Micron-fine structures and entire parts are produced directly from 3D CAD data. Ultrashort-pulsed laser radiation is focused within a transparent work piece and absorbed exclusively in the focus volume by multiphoton processes. In this focus volume, optical and chemical characteristics of the transparent material (for example, glass or sapphire) are changed without cracking in such a way that the irradiated material can be selectively removed by wet-chemical etching. Using a microscanner to move the focus, areas that will subsequently be removed by wet-chemical etching are exposed. This enables microchannels, shaped holes, and structured parts to be produced in glass or sapphire, and in the years ahead this could even be extended to cover complex, assembled mechanical systems (FIGURE 1).

The ISLE process

ISLE is a two-step process. In the first step, material transparent to the laser radiation is modified locally inside the volume (FIGURE 2). For this purpose, ultrashort laser radiation is focused inside the material. In the focus volume, the intensity of the laser radiation must be large enough to enable the absorption by multi-photon processes because the material is transparent at lower intensities. Therefore, laser radiation with pulse duration of picoseconds or shorter and focusing to a few microns are necessary. The material is heated by the absorbed energy during a short time to high temperatures, resulting in large local pressures. Because only a volume of several cubic microns is heated, the material cools rapidly and is quenched in a modified state. For example, single crystalline sapphire is modified to an amorphous form. A connected volume inside the material is modified by scanning of repetitive pulses, which must have at least one contact to the surface of the work piece.

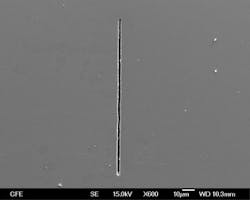

In the second step, the work piece is exposed to a strong acid or lye for some time. Because the material, modified by the laser radiation, is etched much faster than the unmodified material, the modified volume is selectively removed, resulting in hollow structures inside the work piece. The selectivity, that is the ratio of the etching rate of the modified material to the etching rate of the unmodified material, can be as high as 1,000. Therefore, very tight channels, cutting kerfs, and structures with a precision in the range of a few microns can be produced (FIGURE 3).

The ISLE process is characterized by

• high energy efficiency (modification instead of evaporation),

• material efficiency (cutting kerf of a few micro meters),

• high precision in three dimensions (1-μm focus, no debris), and

• scalability to high velocity using lasers with large repetition rates.

These advantages come about because the material is not removed during laser processing but modified locally. Thus, 3D shapes and complex structures can be produced with high efficiency and precision. The main challenge of the process development has its origin in the same fact: Since the modified material is not removed during processing, stress is accumulated in the work piece, which may result in cracking of the material. Therefore, the process development is of ongoing research in Aachen. However, after removing the modified material, the resulting part is free of stress again and stable.

Shape cutting, drilling, and 3D microstructuring

For its main applications in precision mechanics and medical engineering, the ISLE technique is used to cut out parts made of sapphire and glass. The technique achieves extremely narrow widths of cut, e. g., < 5 μm in a material thickness of 1 mm (FIGURE 4). Using a special microscanner, shapes of any configuration can be cut to a precision of 1 μm, with the cut-out part and the resulting shaped hole exhibiting a roughness (Rz) < 1 μm.

Microstructured parts using the ISLE technique are produced in sapphire and glass for precision applications such as watchmaking, micro-optics, and medical engineering.

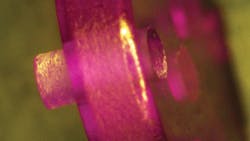

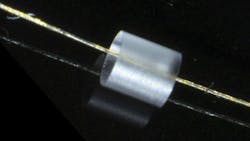

The precision of the ISLE technique is impressively demonstrated by a microtube made of fused silica, which has a length of 1 mm, a diameter of 1 mm, and a wall thickness of 8 μm with a Rz of 1 μm (FIGURE 5). As the material to be removed is exposed in volume with micron precision, parts which have been fitted together, for example a toothed wheel rotating on a shaft, can be produced in already assembled form (FIGURE 1). The ISLE technique renders time-consuming adjustment and assembly work superfluous in the manufacture of complex micromechanical systems.

Microchannels inside glass and sapphire

Microfluidic systems can be produced using the ISLE technique in thermally and chemically resistant materials such as fused silica, borosilicate glass, and sapphire for applications such as those found in medical diagnosis. In fused silica and borosilicate glass, the volume modified by the laser radiation is etched more than 300 times faster than the unmodified glass. The edge angles of the channels reflect this selectivity. Minimal channel diameters of 10 μm with a length of a few mm are feasible. In-volume scanning produces channels, branches, and hollow structures with cross-sections of, for example, 100 μm (FIGURE 6). In sapphire the selectivity is >10.000:1, enabling a minimal channel cross-section of 1-10 μm to be achieved on a length of 1 cm.

Cost effective direct production and scalability

The ISLE technique is the focus of continuous further development at Fraunhofer ILT. The primary goals are to reduce surface roughness, to extend the range of materials that can be processed and to increase the feed speed using new high-power femtosecond lasers with mean outputs of 200-1000 W. We have already demonstrated the scalability of the ISLE technique. For example, fused silica cylinders with a length of 2 cm have been exposed in just a few seconds.

The current development of rapid deflection systems aims to make the production of individual microstructured parts of glass and sapphire possible at cost levels that can only be achieved today by masking techniques or molding processes for identical plastic parts manufactured in large series. New high-speed microscanners are being developed in Aachen to reduce the exposure time for microstructured parts. Thus, direct production of complex shaped microparts directly from digital data (CAD data) is possible and can be scaled from prototypes to small batch series and in the future possibly even to mass production. The potential for scaling up to cycle times of just seconds will make direct industrial implementation possible. In the medium term, this will enable low-cost glass and sapphire parts to be produced that will be more resistant than the present plastic parts and that will be easier to clean and sterilize. In the long term, ISLE also offers enormous potential for individualized mass production because it does not require expensive masks or molding tools, which means that no part-specific fixed costs are incurred.

As a result, the ISLE technique enables the manufacture of prototypes, small series, and large series with transferable process parameters and customized mechanical microsystems with completely new functional properties to be produced more quickly and cheaply. Furthermore, ISLE offers the advantage of unrestricted geometrical freedom, taking series-identical utility properties into account for transparent parts.

Microchannels, holes and 3D micro components are manufactured in glasses and sapphire for micromechanical devices using a new laser production technique called ISLE (In-volume Selective Laser Etching). ISLE is characterized by high energy efficiency (modification instead of evaporation), material efficiency (cutting kerf of a few micrometers), high precision in three dimensions (1-μm focus, no debris), and scalability to high velocity using lasers with large repetition rates. Holes and microchannels for microfluidic devices have been structured in chemical-resistant materials like fused silica, borosilicate glasses, and sapphire.

The authors are all with Fraunhofer ILT (www.ilt.fraunhofer.de) in Aachen Germany. Jens Gottmann can be contacted at [email protected].

More Industrial Laser Solutions Current Issue Articles

More Industrial Laser Solutions Archives Issue Articles