Medium-power laser machine tool increases job shop throughput

Advanced Laser & Waterjet Cutting Inc., Santa Clara, CA, is a job shop servicing a diverse range of applications, from semiconductor, medical, and other high technology areas to architectural, art, and automotive. The company focuses mainly on precision cutting of both metal and non-metal materials, and supports prototyping through large production runs. As its name implies, the organization has utilized laser cutting since its very inception, specifically in the form of a large 4 kW CO2 laser-based machine. Recently, the company added a Coherent Metabeam 400 to its shop. This small machine tool, based on a 400 W CO2 laser, offers increased cutting speed for thinner materials and substantially lower operating costs as compared with the higher-power system. As a result, Advanced Laser & Waterjet Cutting has been able to achieve a significant improvement in production throughput, and is also better able to support certain types of precision processing.

Company background

Advanced Laser was founded in 1994 by Lester Gragg, whose experience included traditional machining together with nine years of work with research lasers for the US Air Force. At that time, Gragg saw that most traditional machine shops didn't have adequate volume in the type of work which requires laser processing to justify purchasing a laser-based machining center. However, he reasoned that if he acquired a laser machine and dedicated his company solely to that type of work, it would be economically viable. That approach proved successful. Today, the company still does not utilize traditional machining or attempt to compete with machine shops or sheet-metal houses by offering services such as machining or forming.

After initial success with laser processing, Gragg soon realized that he could further extend his capabilities by adding a waterjet system to cut a wider variety of materials, such as rubber, foam, and thicker metals. After adding this capability, the company was rechristened Advanced Laser and Waterjet Cutting.

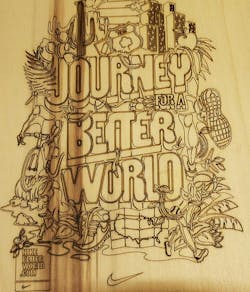

Over time, the company has continued to seek out specialized, precision technologies to expand its portfolio of services. One area of interest was engraving, which is an ideal application for low- to mid-power (50-500 W) CO2 lasers, and therefore a natural extension of the company's capabilities. The company's existing 4 kW laser represented substantial overkill for this application, so the search began for a new lower-power laser machine tool. The firm ultimately encountered and purchased the Coherent Metabeam 400, which is capable of both engraving and cutting.

Configuration and capabilities

The Coherent Metabeam laser machining center integrates a CO2 laser, CNC controller, beam delivery system, assist gas delivery system, drive system, and laser cutting head all into one highly compact machine frame with a standard table size of 4 × 8 ft. It is capable of cutting metals, such as stainless steel, mild steel, aluminum and titanium, in thicknesses of up to 3 mm (depending upon the specific material), as well as wood, plastics, rubber, thin films, composites, and other organics in thicknesses of up to 1.25 in. The system can deliver a precision of up to 0.001 in. (0.0002 in. repeatability), at cutting speeds up to 2,000 in./min.

Job instructions are supplied to the system in much the same way as other digital cutting systems. Part drawings are created in SolidWorks or other application that produces files in DXF, DWG, AI, HPGL, Gerber, JPG, BMP, or TIF format. These are then sent to the cutting system through the software's print command.

Material can be rapidly loaded into the machine, and are held in place by a vacuum bed. Materials and thickness can be switched quickly thanks to a capacitive sensor that accurately maintains the standoff distance from the work piece. An optional camera system facilitates rapid loading of material into the system, which can identify fiducial marks on the work piece - these are used to perform cutting that is referenced to existing features on material regardless of its orientation in the machine. The software can even scale or distort the cutting pattern to correct for any dimensional changes in the material from the originally specified values.

Implementation and benefits

Advanced Laser & Waterjet Cutting utilizes the Metabeam 400 system for cutting thin materials and etching. Typical materials cut include metal shim stock, synthetic rubber (EPDM) gaskets for high vacuum and automotive applications, fabric, acrylic, stainless steel, blued spring steel, and even unanodized aluminum. The firm also regularly etches or marks anodized aluminum and other metals, as well as acrylic. In some cases, the waterjet is used for rough cutting of blanks before precision processing.

When working with these various materials, the company has found that the Coherent system has substantially increased its capacity, and also lowered costs. The increase in throughput comes from several factors. First, the lightweight optics head in the machine can be moved under high acceleration, enabling much more rapid cutting than is possible with the company's larger, 4 kW laser machine.

Increased throughput is further aided by the system's software. Job files are easier to create than for the larger system, which requires very clean DXF files composed of only lines, arcs, and circles. In contrast, this system has no trouble operating from simpler artwork created using applications such as Illustrator or CorelDraw. This cuts down job preparation time.

The ease with which material can be loaded into the system further enhances rapid processing. Specifically, because material is held by a vacuum bed, it doesn't have to be placed with any precision, and no fasteners have to be tightened. The vision system then compensates for the actual orientation of the work piece in the machine. Advanced Laser & Waterjet Cutting has found this feature particularly valuable when processing materials that have previously been silk-screened. Sometimes these materials stretch unevenly, but the system can asymmetrically scale the cutting pattern to adjust for this. The larger laser machine, by contrast, requires the operator to precisely square the blank to the machine.

The increased throughput achieved with the Metabeam also translates into lower job costs. Plus, this system is inherently more economical to operate than a higher-power laser system. One major reason for this is that it uses much less assist gas than the company's bigger system. It also uses far less electricity - which turned out to be an important factor, because Advanced Laser & Waterjet Cutting could install the system without making any changes to its existing electrical supply.

In conclusion, the Coherent Metabeam 400 has enabled Advanced Laser & Waterjet Cutting to expand its business, yet was easy to integrate into the shop, and required minimal operator training. It enables the company to economically cut thin metals, etch metals and plastics, and process a wide range of organic materials. This complements the company's prior capabilities for processing thicker metals with a higher power laser system, or using the waterjet to work other materials that don't lend themselves to laser processing.

About the Author

Lester Gragg

Lester Gragg is president of Advanced Laser & Waterjet (Santa Clara, CA).

Rick Linthicum

Rick Linthicum is vice president of Advanced Laser & Waterjet (Santa Clara, CA).

Frank Gaebler

Director of Product Marketing, Coherent LaserSystems GmbH & Co KG

Frank Gaebler is director of product marketing at Coherent LaserSystems GmbH & Co KG (Lübeck, Germany).