Helping kids lead healthier, happier lives

Ferndale, WA — Nearly 30 years ago, Cascade DAFO Inc. introduced the first Dynamic Ankle Foot Orthosis (DAFO) for pediatric and adult patients who lack some degree of voluntary control of their foot and/or ankle. Unlike rigid AFO braces, the thin, flexible contoured DAFO brace wraps around the entire foot to provide better foot sensation and alignment that allows the patient to learn movement by moving. It also protects the foot and ankle from danger, helps patients to maintain the correct foot/ankle position, encourages mobility, and ultimately improves success with standing and walking skills.

Cascade DAFO takes pediatric orthotics a step further by allowing patients to choose colors, patterns, and decorative graphic elements to personalize their device. For younger patients especially, this is a particularly important feature. “When you see things like the designs they choose, that’s the kids participating in their own healthcare, which makes quite a big difference in whether they want to wear the braces or not,” explained Loretta Sheldon, certified ophthalmic assistant (COA) and director of business development & education at the company.

With both custom and pre-fabricated DAFO designs, and literally hundreds of decorative options for patients to choose from, product tracking and quality control is imperative. From the instant an order comes in to the moment the patient’s foot is outfitted with the final product, progress is meticulously tracked to ensure precise adherence to exacting job specifications.

Originally, efforts to track each DAFO involved recording job numbers, manufacturing dates, and patent numbers using pneumatically powered hand-held engravers, which were heavy, noisy, and difficult for employees to operate for hours at a time. Any mistakes often meant starting over, and these marks could sometimes be difficult to read, potentially leading to warranty questions or delays in reordering. Moreover, when the company’s business grew to include European territories, other challenges presented themselves — for example, the European Union’s requirement that the CE mark be included on each pre-fabricated brace sold in Europe. Hand-engraving tools proved to be ill-suited for this task, leaving Cascade DAFO to consider the costly alternative of reworking all of their thermoforming molds to incorporate the CE mark.

In search of a better solution, Cascade DAFO’s manufacturing engineers contacted Synrad Inc. (www.synrad.com) about using a CO2 laser to mark the polyethylene (PE) shell. Working closely with them, Synrad application engineer Justin Conroy quickly determined that a 25-Watt CO2 laser coupled with an FH Flyer marking head was the perfect solution for marking the compound curved DAFO shell.

The first CO2 laser marking workstation brought such a level of efficiency and consistency to the production floor that another laser marker was soon ordered. “The cost of the laser engraver was pretty much the cost of us taking the man hours and the materials and the time to rework all of our thermal molding,” according to Noah Wass, R&D engineer at Cascade DAFO. “I’m very impressed with how well the machines have held up on our production line. That was a very big concern of ours. It’s just a very, very dusty environment, and to have no issues so far is excellent.”

The Synrad laser marking stations have demonstrated multiple process benefits. By eliminating pneumatic engravers, overall product throughput was increased, and potentially hazardous ergonomic issues were eliminated. In the eyes of their customers — orthotists, therapists, and patients — the permanent engraved marks are unobtrusive in daily use, are easily readable, and lend an air of consistent product quality to the orthoses.

Ultimately, the craftsmanship, quality, and dedication instilled by Cascade DAFO employees are what patients experience when wearing their DAFOs. And the laser markers enable the company to fill more orders each day — so more kids and adults have the opportunity to lead healthier, happier lives.

Laser cladding gold contacts

Aachen, Germany — Keys and keyboards are a common sight in today’s world, both in our personal lives (cars, phones, computers) and in industrial settings. Users expect keys to operate with 100% reliability regardless of how many times they are pressed. At the same time, manufacturers are seeking cheaper production methods and new ways of making more efficient use of expensive, high-quality materials.

Snap domes comprise small contact springs used to make electrical contact and provide tactile feedback in a wide range of keyboard designs. They generally consist of high-quality spring steel which is typically gold-plated (or modified in some other way) to achieve better contact and more reliable switching. As well as having low contact resistance, gold also boasts outstanding resistance to corrosion.

The new micro laser-cladding method replaces the conventional large gold surfaces with small contact spots, clad with a fiber laser beam (FIGURE 1). Using gold powder with grain diameters smaller than 10 µm, the fiber laser beam (< 100 µm dia.) creates contact spots with a diameter and height of < 100 µm. Gold powder is fed through a nozzle into the interaction zone of the laser beam and the substrate material (e.g., stainless steel or nickel alloy). The laser energy melts both the gold powder and a thin surface layer of the substrate to create a welded spot that is metallurgical bonded to the substrate.

One of the biggest advantages of this new method is its material efficiency. To replace the thin gold layer deposited on snap domes by conventional methods, only five selectively welded gold contact spots are needed (FIGURE 2). Initial calculations suggest that this slashes the amount of material required to make the gold contact by 50%–90%.

Preliminary tests carried out by Inovan comprising 100,000 switching operations demonstrate that this new approach does not measurably affect switch service life. In addition, the electrical properties of the gold contact spots correspond to the results obtained from electroplating.

The laser-based method also makes it possible to integrate the fabrication of the gold contact spots into the production of the switch components themselves. This enables rolls of material to be processed and facilitates the efficient production of short-run batches and prototypes.

Cladding a single point takes approximately 50 ms; researchers are currently investigating how to accelerate the process. Experts consider that it should be possible to weld 20 contact spots simultaneously in the future by splitting the laser beam.

Using laser cladding to produce contacts from precious metals is a method that, in principle, is suitable for all metal parts which currently rely on plating techniques to make electrical contacts. Examples include the switches used in cell phones and bipolar plates for fuel cells.

Thanks to Matthias Belting ([email protected]) of the Fraunhofer ILT Coating and Heat Treatment Group for sharing this application with ILS readers.

High-speed package perforation

Bloomfield, CT — Food packaging is often specifically constructed to help preserve product freshness by providing a barrier to moisture, oxygen, and in some cases even light. However, a strong, well-sealed package may also be difficult for the consumer to open, so packages are sometimes scored or perforated to make them open more readily. CO2 lasers have now become a critical enabling technology in performing high-speed precision package perforation for a large-volume manufacturer of ice cream sugar cones.

The packaging challenge

In this particular application, filled ice cream cones are packaged in a material made of 70-80 µm thick paper, coated with an approximately 20 µm thick layer of aluminum. To facilitate opening of the package, the manufacturer perforates through the paper layer while leaving the aluminum layer totally untouched. Preserving the aluminum layer is necessary to maintain the mechanical stability of the package, and avoid compromising its function as a barrier to entry for moisture and oxygen.

When first developing the perforation process, the manufacturer, a large-scale producer of packaging for confectionary, specified that any new method must meet several important criteria. First, it would have to be integrated with their existing production line, in which the packages pass by on a conveyor belt at a rate of three per second. Next, it would need to add very little unit cost to the product. Finally, the new process could not discolor the paper or produce any noticeable debris, since this would produce a negative customer perception in a food product.

The packaging producer saw immediately that no existing mechanical method could meet all these constraints. In particular, no traditional paper cutting tooling could operate at this level of precision on a high-speed conveyor belt. The company turned to laser systems developer Clean-Lasersysteme (www.cleanlaser.de) to create a solution.

The CO2 laser solution

The system developed by Clean-Lasersysteme mates a Coherent (www.coherent.com) GEM-100 laser with focusing optics and a 2D galvanometer mirror-based scanning system. This GEM-100 is nominally a 100 W continuous-wave laser, but here it is pulse width-modulated with a duty cycle in the 60%–80% range to produce a dashed, rather than continuous scribe on the product.

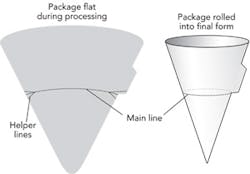

At the point of processing, the paper is flat and triangular in shape. The laser cuts a smooth curved line, with two additional “help” lines at each end to help get the tear started in exactly the right spot (FIGURE 1). The curved perforation then becomes a straight line after the paper is rolled into its final cone shape and glued.

The conveyor belt speed is approximately 1 m/s and never varies. The scanners compensate for this motion and cut while the product is moving. Since laser power is fixed (only the duty cycle, and not the peak power, of the laser is varied), scanning speed is the only process variable. If cuts are too deep or too shallow, then scan speed is altered to re-optimize the process.

Laser considerations

Clean-Lasersysteme selected CO2 laser technology for this application because its 10.6 µm output is readily absorbed by paper, and highly reflected by aluminum. This makes it simpler to cut completely through the paper layer of the package, while leaving the aluminum layer untouched.

Laser-based perforation has enabled a packaging manufacturer to enhance the consumer experience of their product, without substantially increasing production costs. This process would be impractical to implement using non-laser methods, and only the CO2 laser was able to deliver the necessary combination of output characteristics, physical traits, and total cost-of-ownership needed to make this application a success.

(Adapted from editorial material by Frank Gaebler ([email protected]), director of marketing at Coherent Inc., published in the AILU Users Newsletter with permission.)

More Industrial Laser Solutions Current Issue Articles

More Industrial Laser Solutions Archives Issue Articles